Ah, stainless steel. To many, this shiny, versatile metal represents durability and elegance. However, its applications stretch far beyond the aesthetics. Let’s dive into the fascinating world of stainless steel, especially its use as splashbacks, and understand its broader role in various industries.

Ah, stainless steel. To many, this shiny, versatile metal represents durability and elegance. However, its applications stretch far beyond the aesthetics. Let’s dive into the fascinating world of stainless steel, especially its use as splashbacks, and understand its broader role in various industries.

Stainless Steel in Our Kitchens

Perhaps you’ve seen them – shiny surfaces reflecting your morning routine in the kitchen. That’s right; we’re talking about stainless steel splashbacks. These metallic gems are not just for show. Stainless steel splashbacks are favored in many kitchens due to their resilience and easy maintenance. Moreover, with the convenience of stainless steel splashback cut to size, homeowners can now get a perfect fit for any kitchen design.

More than Just a Pretty Face

However, stainless steels journey doesn’t end in our homes. In the vast landscape of industrial settings, this metal stands out as a star player. Facilities equipped with industrial shelving units and storage cabinets, often utilize stainless steel due to its strength and resistance to corrosion. Especially in settings where hygiene is paramount, stainless steel proves invaluable.

Laser Cutting Sydney: Pioneering Precision

For those of you unaware, laser cutting is a technique used to slice through materials with utmost accuracy. It’s like art and science had a baby. The innovation in laser cutting Sydney offers has paved the way for intricate designs and efficient sheet metal manufacturing. Whether you’re designing a unique workbench or crafting delicate metal artworks, the precision of a laser cutting service can be a game-changer.

From Shelving to Storage: The Steel Story

Imagine your workspace. Now imagine it better organized. Stainless steel makes it possible with sturdy shelving units and robust metal shelves. Whether you’re looking for practical storage solutions like a metal storage cabinet or specific industrial shelving, stainless steel is often the go-to choose. It’s durable, sleek, and can handle a lot of weight. Especially in heavy-duty environments, stainless steel’s resilience shines.

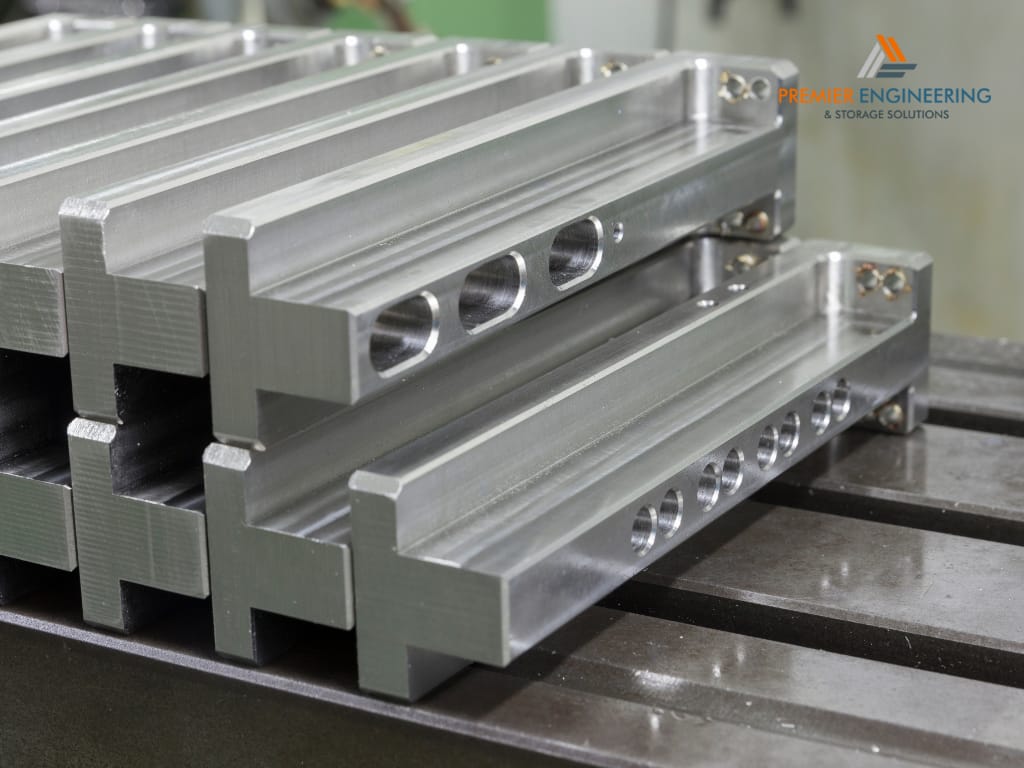

A Closer Look at CNC Services

Now, while laser cutting is impressive, there’s another player in town – the CNC cutting services. By using computer numerical control (CNC) machinery, materials like metal can be sculpted with incredible precision. Sometimes, instead of cutting, a CNC punching service might be employed for specific tasks. It’s another tool in the vast world of manufacturing that complements techniques like laser cutting.

Incorporating User-Centric Queries: An Insight from Premier Engineering

Let’s dive a little deeper into the topic by addressing some common questions many of you might have when considering metal-based storage solutions, laser cutting services, and more. Leveraging the expertise of Premier Engineering, we’ve gathered answers to some frequent queries.

How does stainless steel in splashbacks compare to other materials in terms of durability and maintenance?

Stainless steel splashbacks have become a popular choice in many settings, and for a good reason. They offer a sleek, modern look and are incredibly durable, resistant to high temperatures, and easy to clean. When you compare them to other materials like tiles or glass, stainless steel doesn’t require grout, which can become a breeding ground for mold. Premier Engineering can even provide a stainless steel splashback cut to size, ensuring a perfect fit for your space.

What are the primary advantages of using laser cutting and CNC services in sheet metal manufacturing?

The manufacturing world has evolved significantly, with services like laser cutting and CNC cutting taking center stage. In places like Sydney, laser cutting services have revolutionized how precision parts are made. The primary advantages are accuracy, speed, and the ability to produce intricate designs without physical contact, reducing wear and potential deformation of the metal. Premier Engineering has been at the forefront of adopting these advanced methods, ensuring a product of utmost precision and quality.

Can stainless steel shelving units and storage cabinets be custom-designed to fit specific industrial requirements?

Absolutely! Customization is the essence of modern industrial storage solutions. Whether it’s metal shelves, industrial shelving units, or metal storage cabinets, companies, including Premier Engineering, understand the need for tailored solutions. These can be designed to cater to specific weight capacities, sizes, and configurations, enhancing the efficiency and ergonomics of any workspace.

In conclusion, when it comes to metal-based storage or manufacturing services, staying informed is key. Ensuring that you’re working with experts like Premier Engineering can provide peace of mind and an assurance of quality.