The world of cars is fascinating. It’s more than just high-speed chases and roaring engines. Have you ever paused to wonder how they’re made? How is it possible to shape steel into a sleek and sturdy car body? A significant part of the answer lies in sheet metal manufacturing, specifically, in processes like CNC cutting services and steel metal cutting. Let’s explore this topic together.

The world of cars is fascinating. It’s more than just high-speed chases and roaring engines. Have you ever paused to wonder how they’re made? How is it possible to shape steel into a sleek and sturdy car body? A significant part of the answer lies in sheet metal manufacturing, specifically, in processes like CNC cutting services and steel metal cutting. Let’s explore this topic together.

From Workbench to Wheel

It all starts at a workbench, where creative minds turn concept into design. Engineers use software to create precise blueprints. Next, these plans transition to the manufacturing process, where a piece of sheet metal undergoes transformations.

The Magic of CNC Cutting Services

Here’s where Computer Numerical Control, or CNC, cutting services step in. This advanced technology provides extreme accuracy. This precision ensures the safety and performance of your car. Using a computer to control the process, CNC cutting gives exact shapes and sizes to metal pieces.

The Magic of CNC Punching Services

Here’s where Computer Numerical Control, or CNC, punching services step in. This advanced technology provides extreme accuracy. The precision of the CNC punching service creates precise holes and indentations. This accuracy ensures the safety and performance of your car.

The Role of Steel Metal Cutting

Steel metal cutting plays a fundamental role too. With laser cutting services, these machines precisely slice the steel, turning a simple sheet into a complex component. By doing so, they ensure each part fits perfectly together, like a jigsaw puzzle.

Laser Cutting Services: Precision at its Best

Laser cutting, as the name suggests, uses lasers to cut materials. In the automotive industry, steel laser cutting services are particularly important. They allow manufacturers to achieve a high level of detail and precision. The result? A car that looks sleek, runs smoothly, and most importantly, keeps you safe.

Steel Metal Fabrications: Giving Shape to Cars

Once cut, the pieces of steel are ready for the next stage: steel metal fabrications. Skilled workers or machines bend, shape, and assemble the parts. Ever seen a car body and wondered how it’s so smooth yet durable? The secret lies in this process, were individual pieces fuse together, eventually forming the robust shell of a car.

The Role of Storage Cabinets and Shelving Units

Storage cabinets, particularly metal storage cabinets, play an integral role in this process too. These aren’t the shelving units you see at home. We’re talking about industrial shelving units. These units store everything from the tiny nuts and bolts to the larger body parts, ensuring each piece is within reach when needed.

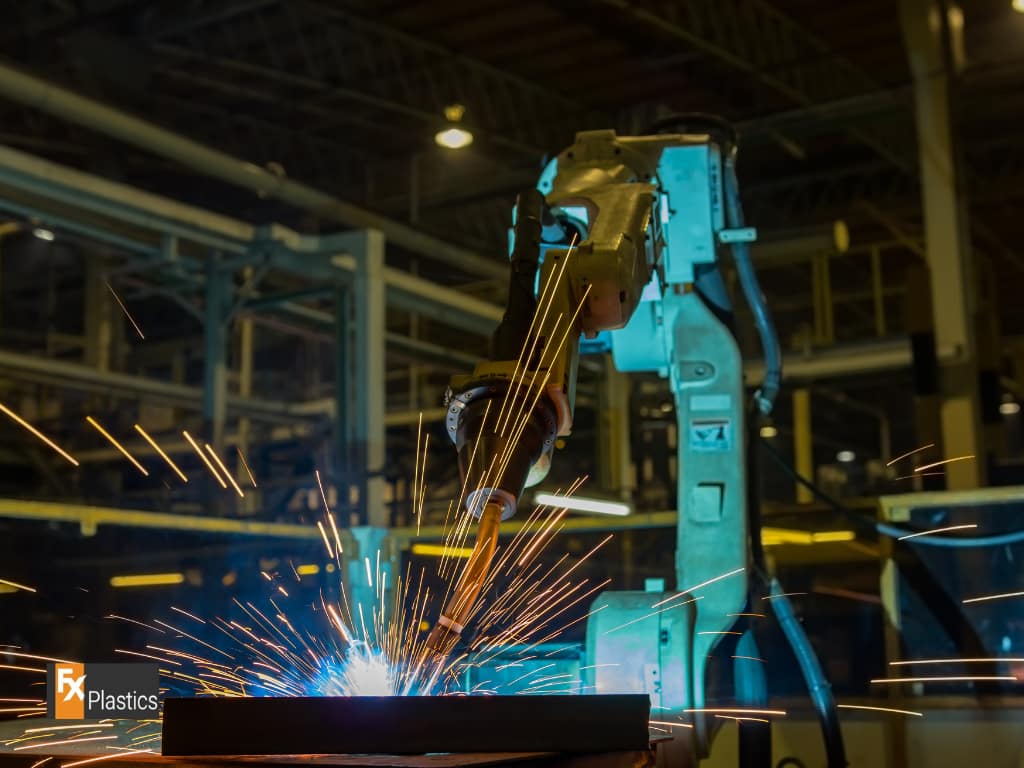

The Final Touch: Welding Services in Sydney and Beyond

Lastly, the separate parts need to come together. Welding services in Sydney and other major cities worldwide join the cut and shaped parts. After the welding process, the car body undergoes a rigorous inspection. This ensures every join, every weld, every piece is perfectly in place.

Delving Deeper into Sheet Metal Manufacturing and Beyond

Intriguing Questions about Sheet Metal Manufacturing

As we immerse ourselves more in the intricate world of sheet metal manufacturing and the automotive industry, it’s only natural to start asking some questions.

The first thought that might cross your mind is about the evolution of these technologies over time. Specifically, you might be curious to know how advancements in CNC cutting services and laser cutting technology have impacted the safety and quality of cars. The answer lies within companies like Premier Engineering, dedicated to leveraging the latest technology in their manufacturing processes.

Over time, as the technology improved, so did the precision and quality of the cuts. This not only made the cars safer but also increased their efficiency. For example, with more precise cutting, car parts fit better together, leading to improved aerodynamics and fuel efficiency.

Sheet Metal Manufacturing in Other Industries

Our exploration doesn’t stop at automobiles. You might be wondering if industries other than automotive use similar processes. Well, the answer is a resounding yes. Industries like aerospace, construction, and even furniture manufacturing utilize processes like steel metal cutting and fabrication. Companies such as Premier Engineering serve a wide range of industries, ensuring high-quality results across the board.

Assembling the Pieces: Beyond Welding Services

You may also be pondering the assembly process. Beyond welding services, what other methods bring together the various parts of a car? A great question indeed! There are several methods used in the automotive industry. These include riveting, where metal rivets join parts together, and bolting, where bolts and nuts fasten pieces.

In some scenarios, adhesives may be used. The method selected often depends on the specific requirements of the vehicle component being assembled. For instance, welding services in Sydney and other cities worldwide are most commonly used for larger parts requiring robust connections, like the car’s frame.

Whether it’s a car you drive, a plane you fly in, or a building you live in, the touch of precision manufacturing is everywhere. Premier Engineering and other such companies play a vital role in shaping the world around us. The next time you see a car or even a shelving unit, you’ll now see more than just an object. You’ll see a testament to human ingenuity and the incredible advancements in technology.