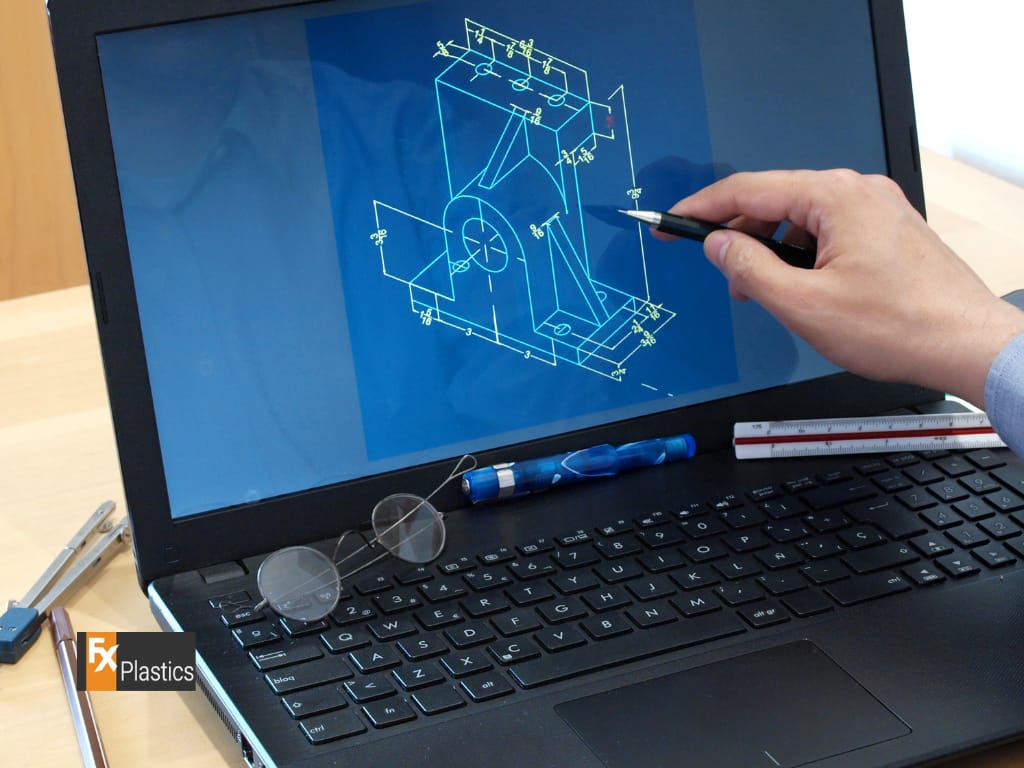

Computer Aided Drawing (CAD) is a technology used for the design and documentation of various kinds of projects, from simple drawings to complex engineering designs. CAD software replaces manual drafting with an automated process, allowing for the creation, modification, analysis, and optimization of a design. This digital framework enhances the designer’s capabilities with tools that can execute repetitive tasks with precision and speed.

Why is CAD Essential for Modern Design and Manufacturing?

In modern design and manufacturing, CAD is indispensable due to its ability to improve the quality of design, enhance communication through documentation, and create a database for manufacturing. CAD systems enable designers and engineers to view objects under a wide variety of representations and to test these objects by simulating real-world conditions. This drastically reduces the time it takes to bring a new product to market and ensures accuracy and customization in design at levels manual processes cannot achieve.

Core Features of CAD Software

What Are the Standard Features Found in Most CAD Programs?

Most CAD programs come equipped with a set of core features that serve as the backbone of all CAD work:

- 2D Drawing: Flat drawings of diagrams and layouts.

- 3D Modelling: Creating three-dimensional objects in a simulated environment.

- Visualization Tools: Rendering and animating designs to see how they would look in real life.

- Drafting Tools: Automated tools that aid in creating accurate dimensions and placements.

How Do These Features Streamline the Design Process?

These features allow for streamlined workflows that are not just faster but also more precise than traditional methods. For example, 3D modelling helps clients and team members visualize the end product more clearly before physical models are built, reducing rework and increasing efficiency. Automated drafting tools reduce errors and help maintain consistent standards across various projects.

Advanced Tools and Their Applications in CAD

What Advanced Tools are Available in CAD Software?

Advanced CAD tools extend basic functionalities to cater to more specialized needs, including:

- Parametric modeling: Allows users to modify design variables interactively.

- Finite Element Analysis (FEA): Used for simulation, FEA predicts how the object would react to physical forces, such as heat, vibration, and other mechanical stresses.

- Computer-Aided Manufacturing (CAM) Integration: This tool integrates design into the manufacturing process directly, reducing the steps needed to produce a prototype or finished product.

Examples of How These Tools Are Used in Complex Projects

In complex engineering projects, such as the development of automotive or aerospace components, these tools are crucial. Parametric modeling enables engineers to test various configurations quickly; FEA helps in predicting and improving product performance under extreme conditions; and CAM integration ensures that the designs are manufacturable, optimizing both the design and the production workflow.

CAD and Material Specific Design: Focusing on Perspex

How is CAD Used for Materials Like Perspex?

CAD is particularly useful when designing for specific materials like Perspex, a brand of acrylic known for its clarity, resistance, and versatility. CAD allows designers to create precise models that take into account Perspex’s unique properties, such as its reaction to heat and its load-bearing capacities.

Benefits of Using CAD for Perspex Cut to Size Projects

Using CAD for Perspex cut to size projects offers several benefits:

- Precision Cutting: Ensures that each piece is cut to exact specifications, reducing material waste.

- Aesthetic Visualization: Designers can experiment with different aesthetics and see how light interacts with Perspex designs before cutting.

- Efficient Revisions: Modifications can be made quickly in the software without the need to produce a new physical prototype each time.

Enhancing Precision in Design with CAD

How Does CAD Ensure Precision and Accuracy in Design?

Computer Aided Drawing (CAD) software is pivotal in achieving high levels of precision and accuracy, which are crucial in design and engineering. CAD programs facilitate this through features like snap-to-grid, parameter constraints, and detailed simulation capabilities. These features allow designers to place and size components with exact precision down to fractions of a millimeter. Additionally, CAD software automates many of the calculations that need to be made during the design process, ensuring that these are both accurate and consistent.

Impact of Precision on Final Product Quality

The precision provided by CAD has a direct and profound impact on the final product quality. Accurate designs reduce the risk of errors during manufacturing, which can lead to defects or failures in the final product. For industries where precision is critical, such as aerospace and biomedical devices, the exactness ensured by CAD can be the difference between success and catastrophic failure. Furthermore, precise designs can lead to better fit and functionality, which are crucial for consumer satisfaction and safety.

Customisation and Modification Through CAD

How Does CAD Facilitate Custom Design and Rapid Modifications?

CAD software excels in its ability to facilitate custom designs and rapid modifications, which are essential for industries requiring unique solutions or quick adjustments. With CAD, designers can easily alter existing models to meet specific needs without starting from scratch, thanks to modifiable parameters and reusable templates. This flexibility allows for endless variations of a design without compromising the integrity or detail of the original.

CAD Software Integration with Manufacturing Processes

How CAD Software Interfaces with Modern Manufacturing Technology

CAD software interfaces seamlessly with modern manufacturing technologies, such as Computer-Aided Manufacturing (CAM) systems and 3D printers. This integration is facilitated by the use of universal file formats like STL (for 3D printing) and G-code (for CNC machines), which allow designs created in CAD to be directly interpreted by manufacturing machines. This direct pathway from digital design to physical production enhances both the speed and accuracy of the manufacturing process.

The Role of CAD in Streamlining Production Lines

CAD plays a crucial role in streamlining production lines by allowing for detailed pre-production testing and assembly analysis, reducing the time and resources spent on trial and error. The precise models created in CAD ensure that all components fit together as intended before production begins, minimizing costly delays and material waste. Additionally, the integration of CAD with production scheduling tools helps optimize the manufacturing process, ensuring that resources are used efficiently and products are delivered on schedule.

Future Developments in CAD Technology

What Are the Emerging Features and Capabilities in Newer CAD Versions?

The future of CAD technology is marked by the integration of artificial intelligence (AI) and increased interoperability across different platforms. Emerging features include smarter AI algorithms that can predict user actions and automate more complex design tasks, and enhanced cloud-based collaboration tools that allow teams to work together in real time from anywhere in the world. Additionally, augmented reality (AR) and virtual reality (VR) are becoming integrated into CAD systems, allowing designers to interact with their creations in a three-dimensional space.

Predictions for Future CAD Technologies and Their Potential Impact

The integration of AI in CAD is expected to significantly reduce the time it takes to bring a product from concept to market by automating routine tasks and optimizing design processes. AR and VR will revolutionize how designs are presented and reviewed, offering a more intuitive and immersive experience. These advancements will not only enhance productivity but also foster innovation, as designers will have more time and better tools to explore creative solutions.

Choosing the Right CAD Software for Specific Needs

Factors to Consider When Selecting CAD Software

Selecting the right CAD software involves considering several factors:

- Functionality: Does the software have the specific features and tools needed for your industry or project type?

- Usability: How user-friendly is the software, especially for team members who may not have extensive technical training?

- Compatibility: Can the software integrate smoothly with other tools and systems in use?

- Support and Updates: Does the software provider offer good customer support and frequent updates?

Tips for Testing and Evaluating CAD Software Before Purchase

Before committing to a CAD software purchase, it is crucial to:

- Take advantage of free trials to test the software’s capabilities and ensure it meets your needs.

- Check user reviews and case studies to understand others’ experiences with the software.

- Evaluate the software with a real project to get a practical sense of how it works under your specific conditions.

- Consult with industry peers who have experience with different CAD systems to gain insights from their expertise.

Conclusion

As we look toward the future, the continued evolution of CAD technology promises even greater advances in design and manufacturing. Businesses and professionals in these fields are encouraged to embrace these tools, leveraging the latest CAD technologies to stay competitive in a rapidly changing world. The potential for CAD to further enhance design and production efficiency is vast, and those who capitalize on its capabilities will likely lead their industries in innovation and quality.