Perspex is a clear, durable plastic often used instead of glass. It’s also known as acrylic or acrylic glass. You’ll find it in signs, protective barriers, shop displays, and even furniture. In many industries across Australia, especially in Perspex Cutting Sydney, it’s a popular choice because it’s lightweight, weather-resistant, and easy to work with.

But there’s more to Perspex than just choosing the material. Thickness plays a big role in how your project turns out. Whether you’re building an acrylic screen, a Plastic Display, or a piece of custom signage, using the wrong thickness could lead to problems down the line. That’s why understanding your needs before cutting starts is so important.

Common Mistakes People Make

A common mistake in Perspex Cutting Sydney is picking a sheet that’s too thin for the job. It might seem like a cheaper option at first, but if it bends or cracks later, you’ll end up spending more to replace it.

Another issue is not thinking about how the item will be used. For example, people sometimes use thin sheets for wall-mounted Plastic Display units. But if they hold heavy items or are used in busy areas, they can break easily.

It’s also easy to overlook how the thickness will impact the cutting method. Some thicknesses don’t cut well with laser tools, especially for Laser Cutting Western Sydney services. That can lead to rough edges or even burning marks.

How Thickness Affects Design and Fabrication Results

Impact on Strength and Stability

Thicker Perspex is naturally more rigid. If your project involves shelving, partitions, or weight-bearing parts, thicker sheets provide better support. On the other hand, thin sheets can bend or bow if they’re not supported properly. For wall signs or hanging Plastic Display items, that’s something to think about.

Also, outdoor items exposed to wind or sunlight should use thicker material to stay in good shape. In Sydney’s changing weather, strength equals durability.

Flexibility and Bending Concerns

Some projects benefit from flexibility, but others don’t. If you’re creating curves or lightweight signs, a thinner sheet might be helpful. But for clean lines or mounted panels, bending is a problem.

During the Design and Fabrication stage, professionals consider how the thickness will react to different cutting tools and environments. If the material flexes too much, even the best machine can’t guarantee a perfect cut.

Choosing the Right Thickness for acrylic screens and Protective Panels

Acrylic screens have become more common in recent years. From office counters to shop registers, they’re everywhere. But not all screens are created equal—thickness is key.

Popular Thicknesses for Sneeze Guards and Barriers

For protective acrylic screens, the typical thickness ranges from 4.5mm to 6mm. This size offers good visibility while staying strong enough to resist knocks or accidental bumps.

In busier places like cafes or retail stores, thicker sheets (around 8mm) might be needed. They’re better at handling everyday wear and tear.

What Works Best for Public Spaces and Offices

If your screen needs to be moved often or attached with clamps, you’ll want something that won’t crack easily. Thicker acrylic helps here too.

A helpful tip: always match your thickness to how the screen will be used. This ensures safety for both staff and customers—and keeps your Perspex Cutting Sydney project up to standard.

What Thickness Is Best for Plastic Display Projects?

Recommended Sizes for Signs, Menu Holders, POS Displays

For light Plastic Display items like menu stands or tabletop signs, 2–3mm sheets usually work well. They’re easy to cut and mount. For hanging displays or items that get touched often, 4.5mm to 6mm sheets offer better stability.

Freestanding signs or donation boxes should go even thicker—maybe 8mm or more—so they don’t wobble or break under pressure.

Indoor vs Outdoor Use

If your display is going outside, don’t go too thin. Thin sheets can warp in the sun or crack in cold. For Perspex Cutting Sydney jobs outdoors, 6mm to 10mm is often the safe choice.

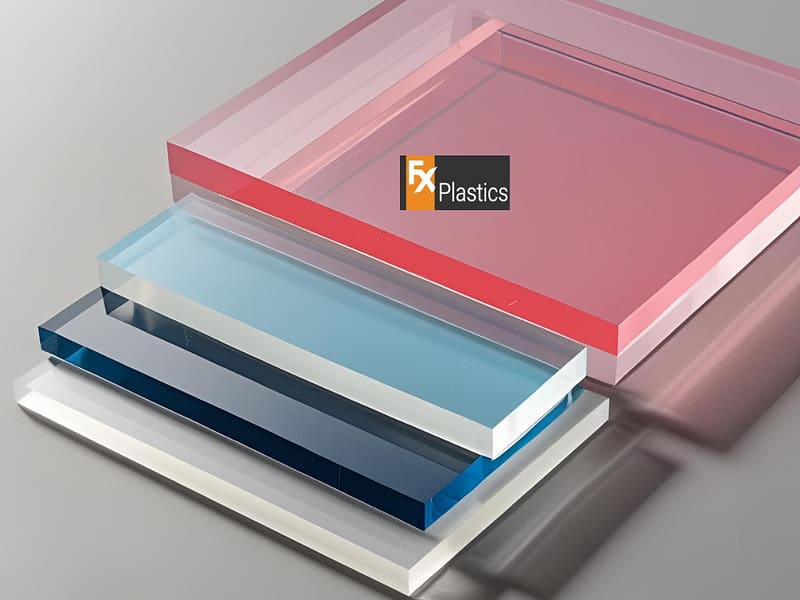

Also, remember that thicker acrylic holds color better. If you’re using coloured sheets for branding or decorative looks, they’ll stay vibrant longer in the sun.

Thickness Guide for CNC routing and machining

When working with CNC routing and machining, the right thickness ensures clean cuts and strong results. Machines can handle a wide range, but each has its sweet spot depending on the project.

How CNC Cutting Handles Different Thicknesses

For detailed patterns or lettering, thinner sheets (around 3–5mm) are easier to shape and less likely to chip. For large signs, fixtures, or boxes, going up to 10mm or even 12mm is better.

With CNC routing and machining, material thickness also affects how many passes the machine needs. Thicker sheets require more time, which can raise costs—but you get more strength in return.

Tips to Avoid Cracking or Chipping

Always choose a thickness that suits the design. Thin acrylic can crack under too much pressure from the machine. If you’re unsure, it’s always safer to go slightly thicker.

If you need professional help, FX Plastics is a trusted Acrylic Fabrication company that offers custom cut acrylic in a range of colours, sizes, and thicknesses. They provide expert CNC routing and machining as well as CNC laser cutting, making them a great option for anyone needing precise results in Perspex Cutting Sydney.

Is Your Project Right for Laser Cutting Western Sydney Services?

Laser Cutting Western Sydney is popular for precision cuts, sharp edges, and fast turnaround. But not every thickness works well with lasers.

How Laser Machines Handle Various Thicknesses

Most laser cutters handle up to 10mm thick acrylic easily. Anything above that can slow down the process or reduce edge quality. For signage, displays, or acrylic screens, the 3mm to 6mm range usually gives the best results.

Thicker materials may also need multiple passes, which can slightly melt the edges or leave marks. That’s why experienced operators adjust the settings based on thickness.

What Gives the Cleanest Edge?

Laser cutting gives a glossy, flame-polished edge on clear acrylic. But the best finishes come from sheets between 3mm and 6mm thick. If your project needs clean corners or tight curves, that’s the sweet spot.

So, when working with Laser Cutting Western Sydney, it’s smart to talk to your cutter before placing the order. That way, you avoid surprises.

Tips for Picking the Right Thickness for Perspex Cutting Sydney

Match Your Project Type to a Recommended Size

Light signs and displays: 2–4mm

Protective acrylic screens: 4.5–6mm

Outdoor or structural items: 8–10mm

Decorative panels: 6mm or higher for deeper effects

Choosing wisely helps your item last longer and look better.

When to Ask for Help from Professionals

Don’t guess. If you’re not sure what thickness you need, just ask! Professionals in Perspex Cutting Sydney can walk you through your options. They’ll suggest the best fit for your design, use, and budget.

Before ordering, double-check:

What is the sheet being used for?

Will it hang, stand, or move?

Does it need to be clear, coloured, or frosted?

Is it being cut by CNC routing and machining or Laser Cutting Western Sydney?

Getting those answers right from the start saves time, money, and stress later.