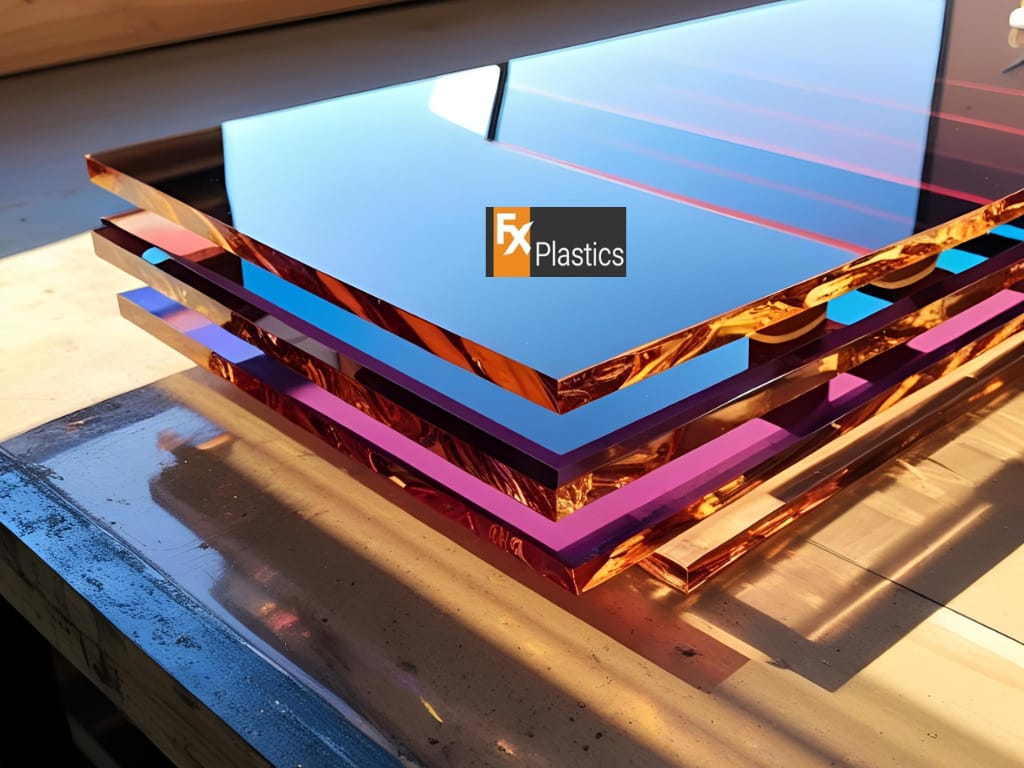

If you’ve ever tried to cut acrylic by hand, you know how tricky it can be. Edges chip easily, lines go wonky, and it’s hard to get a clean finish. That’s where laser cut acrylic changes everything. With high-powered laser machines, your acrylic sheet is cut with a precise beam of light—no blades, no vibration, and no mess. This method leaves smooth, flame-polished edges that don’t need extra sanding or trimming.

The laser melts through the acrylic exactly where it’s programmed to, following your design file down to the finest curve or angle. Whether you’re making a sign, splashback, display panel, or a custom art piece, the results are sharp, consistent, and ready to use.

Why Laser Cutting Works Better Than Traditional Saws

Traditional saws can do the job, but they also bring problems—dust, jagged edges, even cracking or burning. They require careful measuring, strong hands, and a fair bit of cleanup afterward. In contrast, laser cutting is fast and efficient. There’s no physical contact with the material, so there’s less risk of damaging your sheet. The laser cuts are clean from the first pass, whether you’re working on thin sheets or thicker panels.

When you choose laser cut acrylic, you’re getting a professional-grade finish right out of the machine. No more patching up rough edges or wasting material on bad cuts. It’s the smarter way to get results you’ll be proud to show off—especially for projects that need high visual appeal.

Say Goodbye to Measuring Errors with Made-to-Order Acrylic Sheets

How Pre-Cut Acrylic Sheets Sydney Eliminate Guesswork

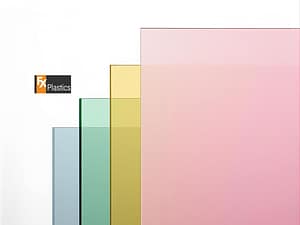

One of the biggest headaches when working with acrylic is getting the sizing right. Measure once, cut wrong—and you’re left with wasted material and frustration. That’s why ordering Acrylic Sheets sydney pre-cut to your exact dimensions is a total game changer.

By ordering your acrylic sheet cut to size, you get precision from the start. You won’t have to worry about trimming, sanding, or getting the right fit. You simply unbox and install—no measuring tape stress or second-guessing needed.

Save Time on Trimming and Sanding

Even small projects can become time-consuming when you’re doing your own cutting. Trimming acrylic manually is messy, and sanding the edges takes up valuable time. Not to mention, it’s easy to crack the sheet if you’re not careful.

With professionally laser cut acrylic, there’s no need to clean up or correct your cuts. You get clean, polished edges and perfect measurements from the get-go—saving you time on every job.

How CNC Cutting Services Help You Get It Right the First Time

Why Professionals Use CNC Cutting Services for Accuracy

Whether you’re building signage, prototypes, or parts for manufacturing, precise cuts are everything. That’s where cnc cutting services come in. CNC (Computer Numerical Control) uses digital precision to cut even the most complex shapes or intricate designs into acrylic.

It’s perfect for repeat jobs or bulk orders because the results are consistently flawless. If you’re working on a project that needs sharp corners, curves, or holes cut in exactly the right place, CNC is the go-to.

Perfect for Complex Shapes, Curves, and Repeat Jobs

Manual cutting tools just can’t match the accuracy of CNC. When every millimetre counts, CNC guarantees tight tolerances, neat finishes, and zero mistakes. It also saves on material because you won’t have to recut or waste sheets from errors.

If you’re producing multiple identical parts or working with complicated layouts, cnc cutting services are the reliable choice to get it right the first time—every time.

The True Cost of Cutting Acrylic Yourself

Do You Need Special Tools? (Yes!)

Cutting acrylic properly isn’t as easy as it seems. You’ll need fine-tooth blades, clamps, protective eyewear, and a steady hand. On top of that, you’ll probably need sandpaper or polish to fix up the edges. It adds up—not just in cost, but in time.

Common Problems with DIY Cutting—Cracks, Rough Edges, Poor Fit

Without the right tools and experience, it’s easy to chip, crack, or melt acrylic during a cut. One wrong move and the whole sheet could be unusable. And if your cuts are uneven or don’t line up, the whole project can fall apart.

That’s why so many customers now choose laser cut acrylic—for a professional finish with no stress or risk.

Why Ordering Cut-to-Size Acrylic Saves You Time on Every Project

Skip the Measuring, Marking, and Cutting

Think about the time you spend measuring, double-checking, cutting, and correcting mistakes. Now imagine skipping all that. That’s the power of made-to-order acrylic. With your dimensions pre-cut by experts, your materials arrive ready to go.

You can go straight to the build or install phase, whether you’re working on signs, panels, displays, or home DIY.

Delivered Ready to Install or Assemble

When your Acrylic Sheets sydney arrive pre-cut, you get exactly what you need—no more, no less. No offcuts, no sharp dust, and no uneven edges. Just clean, custom-sized acrylic sheets you can put straight into your project. The result? A smoother process, faster turnaround, and a more professional finish.

Laser Cutting Western Sydney Services That Deliver to Your Door

How Laser Cutting Western Sydney Providers Make Ordering Easy

Looking for local, reliable service? Laser Cutting Western Sydney providers make it easy to get exactly what you need—fast. Whether you’re ordering one sheet or a full batch, local experts offer custom sizing, precision laser cutting, and expert advice.

They can help with design files, recommend materials, and guide you on thickness or finish—perfect for both beginners and professionals.

Local Cutting, Local Delivery, Fast Service

With Laser Cutting Western Sydney, you don’t have to wait for overseas shipping or drive across town. Many suppliers offer next-day turnaround or local delivery so your project can keep moving. It’s perfect for tradies, creatives, event stylists, and small businesses who want fast, dependable results without the hassle.

From Custom Signs to Home Projects: Who Benefits from Cut-to-Size Acrylic?

Perfect for Signage, Displays, Splashbacks, and DIY Furniture

Laser-cut, ready-to-use acrylic is incredibly versatile. You can use it to make eye-catching signage, protective screens, custom tabletops, or even artistic wall panels. Many designers now use laser cut acrylic for kitchen splashbacks, shelving, and retail displays because it’s lightweight, easy to clean, and looks sleek.

Builders, Artists, and Retailers Love the Convenience

From builders needing a fast fit to artists creating custom installations, cut-to-size acrylic makes every job easier. And with a growing demand for neat finishes and modern looks, more and more businesses and homeowners are turning to Acrylic Sheets sydney suppliers for ready-to-use, perfectly sized materials.