Greetings, readers! Today we delve into the intricate world of acrylic sheets manufacturing. The objective? To make this intriguing process easily understandable to you.

Greetings, readers! Today we delve into the intricate world of acrylic sheets manufacturing. The objective? To make this intriguing process easily understandable to you.

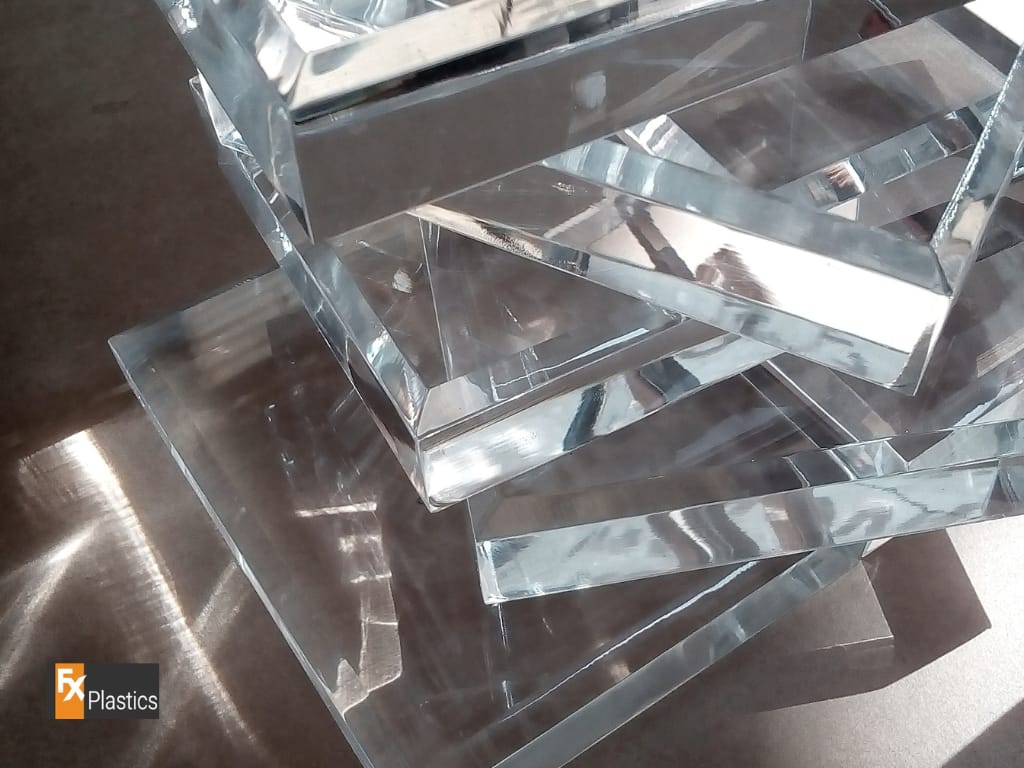

Unveiling the Mystery: What Are Acrylic Sheets?

At the core of many creations, acrylic sheets are plastic materials known for their strength and transparency. They’re often used in place of glass, which can be more fragile. Many industries, especially in Sydney, employ these sheets in a wide range of applications.

Raw Material to Final Product: The Acrylic Fabrication Process

Acrylic sheets start their journey as raw material – a monomer in liquid form. This monomer undergoes a process called polymerization. In simpler terms, small molecules combine to form a larger, more complex structure. The result? A solid, transparent material we know as acrylic.

The fabrication doesn’t end here, though. To shape the acrylic sheets into their final forms, a method known as CNC saw cutting is often employed. This is where Computer Numerical Control (CNC) technology comes into play. Highly precise and efficient, CNC saw cutting ensures the acrylic sheets are cut accurately to meet their destined specifications.

Cutting to Precision: CNC Laser Cutting in Sydney

For more detailed and intricate designs, CNC laser cutting is used. Sydney is a hub for this advanced technique. The laser, controlled by a computer, burns or melts away the material, leaving a beautifully cut edge. Interestingly, it can cut through thick acrylic sheets with minimal waste and superior finish.

The Glossy Finish: Diamond Polishing

Now, let’s move on to the final stage: diamond polishing. Diamond polishing is a method used to achieve a smooth, glossy finish. As the name suggests, a diamond polisher is used, which ensures that the edges of the acrylic sheet are as clear and polished as the surface.

Applications: Where Do We See Acrylic Sheets?

Acrylic sheets are used in various applications due to their durabili ty and versatility. From plastic displays in retail stores to protective shields in the medical field, especially during the Covid-19 pandemic, acrylic sheets play a critical role.

Hygiene screens, another application of acrylic sheets, have gained popularity recently. They’re a type of protective shield used to prevent the spread of viruses. A significant development we’ve seen in Sydney is the use of acrylic sheets for Perspex cutting. This involves cutting acrylic sheets to create customized designs.

In the design and fabrication industry, CNC routing and machining techniques are often used to manufacture complex acrylic structures. These could range from furniture items to car parts. In Sydney, plastic fabricators take this a step further by crafting unique, bespoke designs.

Unlocking the Mysteries of Acrylic Sheets: Responding to Your Queries

Hello again, readers! We’ve received some thoughtful questions about our previous discussion on acrylic sheets manufacturing. Let’s dive in to answer them, further demystifying the fascinating process at the heart of companies like Fx Plastics.

On Safety Measures in Acrylic Fabrication

Firstly, safety is indeed paramount in the acrylic fabrication process. Companies like Fx Plastics take various precautions to ensure safety, especially during CNC saw cutting and laser cutting stages. The use of safety glasses, protective clothing, and appropriate training are common practices. Furthermore, machines are regularly inspected and maintained to prevent any unexpected incidents.

Environmental Impact and Sustainable Practices

Your second question revolves around the environment – an essential topic. The manufacturing process of acrylic sheets, like many industrial processes, can have environmental impacts. However, Fx Plastics and others in the industry are continually seeking more sustainable practices. This includes energy-efficient machinery, recycling initiatives, and research into more eco-friendly materials.

Demand Shifts Amid a Pandemic

The final question highlights the impact of the Covid-19 pandemic on the acrylic sheets industry. Indeed, we’ve witnessed a significant shift. Demand for certain applications of acrylic sheets, such as Covid-19 protective shields and hygiene screens, has skyrocketed. Fx Plastics, for instance, has been instrumental in responding to this increased need, swiftly adapting their manufacturing processes to meet this demand.

Wrapping Up: The Ever-Evolving Acrylic Sheets Industry

In conclusion, the acrylic sheets industry is complex and ever-evolving. Starting with a simple liquid monomer and ending as a versatile, robust material, the process is truly fascinating. Each stage – from CNC saw cutting to diamond polishing – contributes to the final product’s quality and appeal. Whether it’s providing protective shields in a pandemic or enhancing the aesthetics of a retail store, acrylic sheets have undoubtedly made their mark.

Thank you for engaging with these topics and raising such insightful questions. Remember, the world around us is filled with intricate processes and stories – even in the seemingly simple sheet of acrylic in a protective shield or display. Stay curious, and until next time, happy learning!