Diamond polishing cuts vary widely, each designed to enhance the stone’s natural brilliance and aesthetic appeal. The most common cuts include the Round Brilliant, Princess, and Emerald cuts, each offering unique characteristics that appeal to different tastes. The Round Brilliant is known for its exceptional fire and light performance, the Princess cut offers a modern and angular look, while the Emerald cut is valued for its clarity and iconic stepped facets.

Importance of Polishing in Enhancing Diamond Brilliance

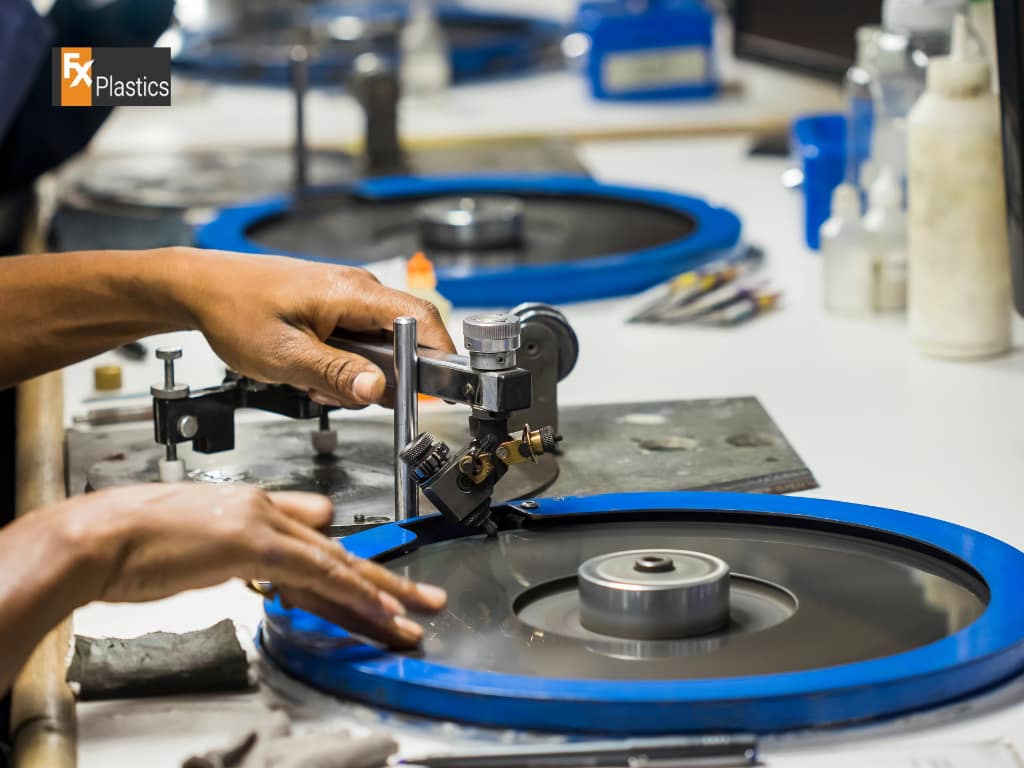

Polishing is a critical step in the diamond polishing finishing process that enhances the gem’s natural beauty. Proper polishing ensures that each facet of the diamond is smooth and well-defined, maximizing light reflection and refraction within the stone. This not only improves the diamond’s brilliance but also its overall appearance, making polishing an indispensable skill in diamond craftsmanship.

Detailed Look at Popular Diamond Cuts

Round Brilliant Cut: Polishing Techniques and Display Tips

The Round Brilliant cut, with its 57 or 58 facets, is the most popular diamond shape due to its ability to maximize light return.

- Polishing Techniques: This cut requires precise facet alignment to ensure optimal light behavior. The polishing process involves careful control of facet angles and the use of progressively finer abrasives to achieve a mirror-like finish.

- Display Tips: When displaying a Round Brilliant cut diamond in a plastic display, use lighting that enhances its fire (dispersion of light into the colors of the spectrum). Direct light sources that can move around the diamond are ideal for showcasing its scintillation effect.

Princess Cut: Specific Polishing Challenges

The Princess cut is renowned for its sharp angles and contemporary style.

- Polishing Techniques: This cut involves complex facet patterns that require meticulous polishing to maintain the geometric precision necessary for its brilliance. Special attention must be given to the corners, which are prone to chipping.

- Display Tips: For the Princess cut, utilize a plastic display that protects its pointed edges while still allowing light to enter from various angles to showcase its unique sparkle.

Emerald Cut: Achieving Precision

The Emerald cut is celebrated for its open table and step-cut facets which emphasize the clarity of the stone.

- Polishing Techniques: Precision is key in polishing an Emerald cut diamond polishing. The polisher must ensure that each step facet is perfectly flat and that the edges are straight and sharp, which enhances the hallmark ‘hall of mirrors’ effect.

- Display Tips: Use a plastic display that allows for ample light from the sides and top to highlight the distinct clear and linear facets. Avoid overly bright direct light, which can expose any inclusions more readily than in other cuts.

Innovative Polishing Techniques for Specialty Cuts

Marquise and Pear Cuts: Handling the Points

These cuts feature pointed ends that can be particularly challenging to polish and protect.

- Polishing Techniques: Extra care is required to polish the tips without causing damage. Polishing these ends involves using smaller tools and adjusting the pressure applied during the polishing process.

- Display Tips: Plastic displays for these cuts should include custom mounts that support the points securely, preventing stress that could lead to chipping.

Heart-Shaped Cuts: Emphasizing Symmetry

The Heart-shaped cut requires a balanced approach to ensure the symmetry of its lobes and point.

- Polishing Techniques: Symmetry is crucial, so each side must be polished to identical proportions. The cleft of the heart (the dip at the top) requires delicate handling to define it sharply without over-polishing.

- Display Tips: Opt for a plastic display that positions the diamond front and center at eye level to emphasize its romantic shape, with a backdrop that enhances its color and brilliance.

Polishing Techniques for Enhanced Light Performance

Optimizing Facet Angles for Maximum Brilliance

The optimization of facet angles is a critical aspect of diamond polishing that significantly affects a diamond’s light performance. Precise facet angles are designed to maximize light return through the top of the diamond, enhancing both brilliance (white light reflections) and fire (color dispersion). Advanced computer software and precision cutting tools are used to calculate and execute these angles, ensuring that each facet reflects light to the viewer’s eye optimally.

The Role of Finish in Light Reflection

The final polish of a diamond plays a crucial role in its ability to reflect light. A high-quality polish eliminates tiny surface defects that can detract from the diamond’s brilliance and clarity. The smoother the surface, the more effectively light can enter and exit the diamond, leading to greater sparkle. In display settings, the quality of the polish should be considered, as it can influence how a diamond interacts with light sources, affecting its overall presentation.

Using Plastic Displays to Highlight Polished Diamonds

Design Considerations for Plastic Displays

When choosing plastic displays for diamonds, several factors need consideration to ensure they enhance the visual appeal:

- Material Transparency: Opt for high-quality acrylic or other clear plastics that offer crystal-clear visibility without distortion.

- Shape and Size: Select designs that complement the diamond cut. For example, rounded or angular bases that mirror the diamond’s shape can enhance its geometric properties.

- Security Features: Ensure the display securely holds the diamond, especially for high-carat or uniquely shaped stones, to prevent tipping or rotation that could hinder proper viewing.

Lighting and Placement in Plastic Displays

Effective lighting and strategic placement are key to showcasing the polished diamonds:

- Directional Lighting: Use spotlights or LED lights positioned to create dramatic shadows and highlights, accentuating the diamond’s cut and polish.

- Consistent Light Temperature: Maintain consistent white light to accurately display the diamond’s true color and avoid color casting from surroundings.

- Elevated Positioning: Position diamonds at eye level within the display, allowing easy viewing from multiple angles without the need to handle the stone.

Conclusion

The integration of expert polishing skills with strategic display methods is essential for maximizing both the aesthetic appeal and commercial value of diamonds. Retailers and exhibitors are encouraged to invest in both high-quality polishing and innovative display solutions to captivate potential buyers and diamond enthusiasts alike, ensuring each diamond is viewed in its best light.