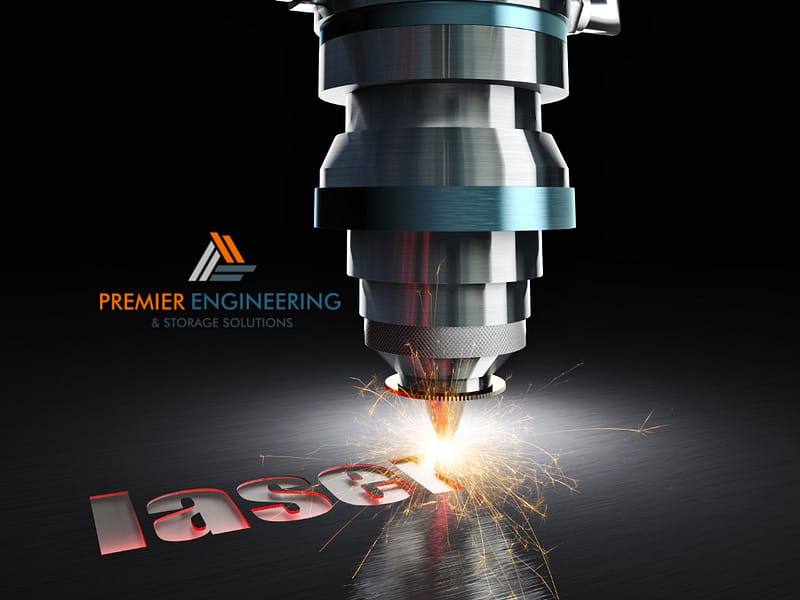

In the world of manufacturing, laser cutting has completely transformed how materials are shaped and processed. Known for its incredible precision, laser cutting uses a focused beam of light to cut through various materials with unparalleled accuracy. This innovative approach has replaced many traditional methods, making it a preferred choice for industries that require detailed and high-quality results.

The demand for laser cutting service has grown significantly in recent years. Businesses across industries—from automotive to electronics and even creative fields like jewelry design—rely on this technology for its reliability and efficiency. Whether you’re working with intricate patterns or need uniformity across multiple pieces, laser cutting ensures exceptional results every time.

Compared to traditional cutting techniques, laser cutting offers numerous advantages. It provides cleaner cuts, minimizes waste, and works on a wide range of materials. In this guide, we’ll explore the top benefits of laser cutting, including its precision, versatility, and efficiency, and why it’s a must-have for modern manufacturing processes.

Exceptional Precision and Accuracy

One of the biggest reasons manufacturers choose laser cutting is its incredible precision. Whether you’re working on detailed designs or components with tight tolerances, this technology ensures every cut is accurate. The concentrated laser beam makes clean cuts that leave no jagged edges or imperfections, eliminating the need for additional finishing processes.

Why CNC laser cutting ensures consistency across multiple pieces

For projects that require large-scale production, CNC laser cutting is a game-changer. CNC, or computer numerical control, allows the laser to follow a programmed design with exact precision. This means every piece in a batch will have identical cuts, ensuring consistency and quality, even in high-volume production.

The role of laser technology in minimizing errors

Errors in manufacturing can lead to wasted materials and time. Laser cutting reduces this risk by using advanced software to guide the cutting process. The laser follows the design perfectly, minimizing human error and ensuring that even the most intricate patterns are executed flawlessly.

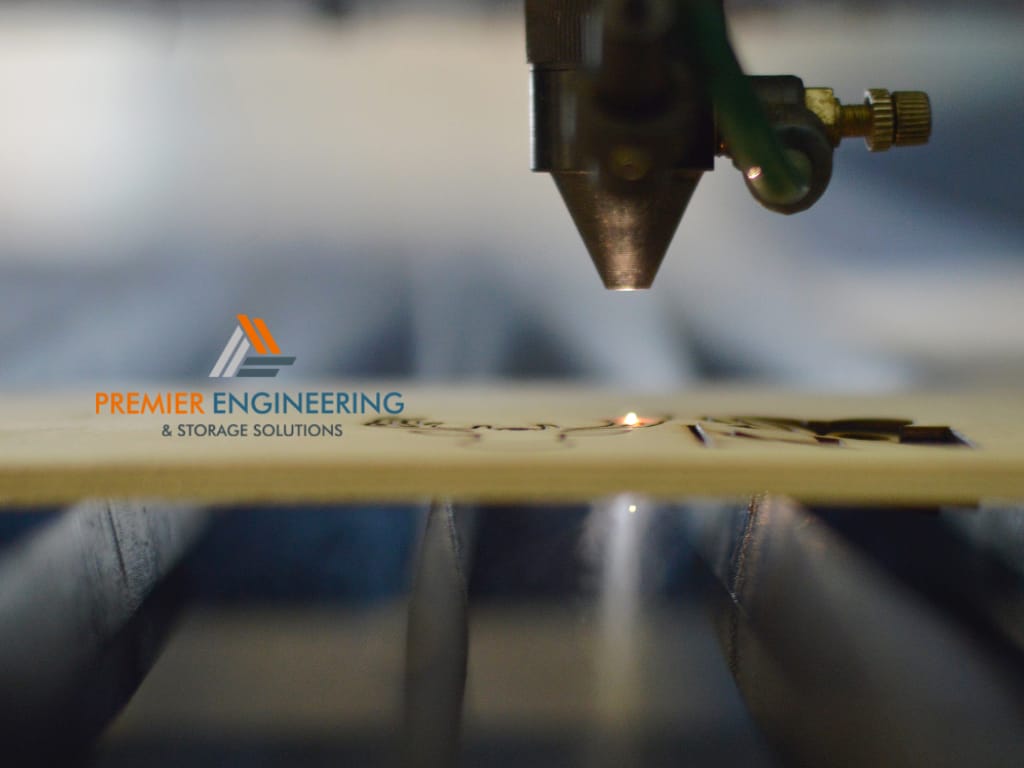

Versatility Across Materials

Another key advantage of laser cutting is its ability to work with a wide variety of materials. Whether you’re cutting metals like steel and aluminum, non-metals like acrylic and wood, or even delicate materials like fabric, laser cutting service adapts to meet your needs.

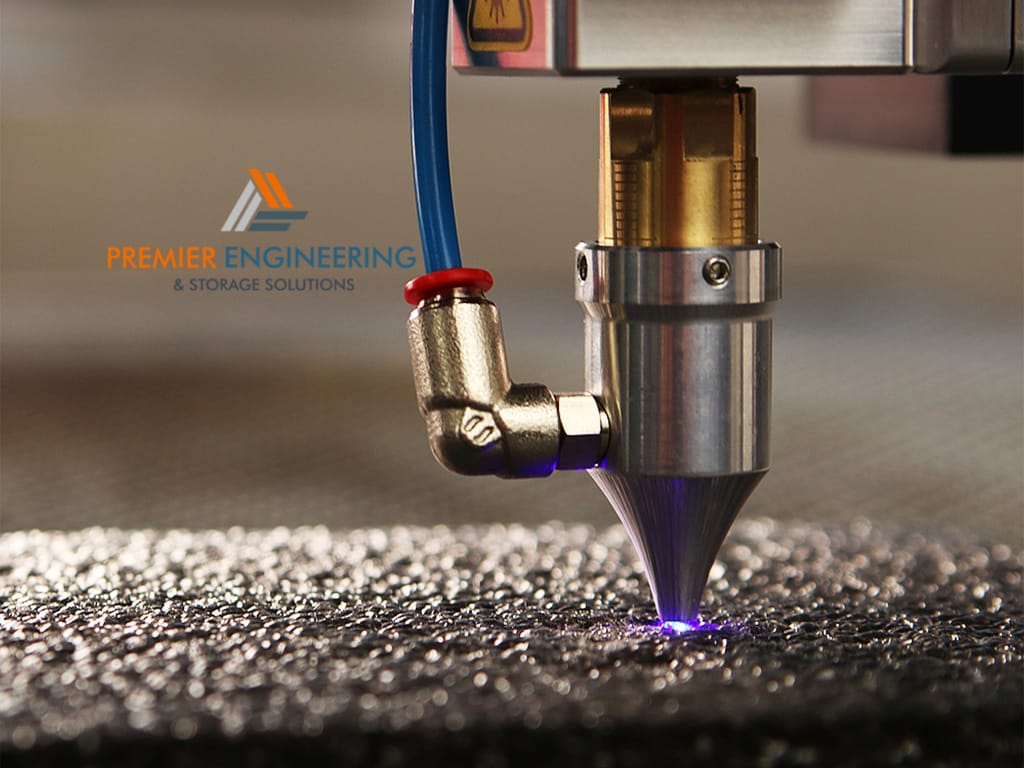

Why CNC laser cutting works for both thick and thin materials

With CNC laser cutting, the laser’s power can be adjusted to handle different material thicknesses. For instance, it can easily cut through thick steel sheets for industrial applications or thin acrylic for decorative purposes. This versatility makes it an excellent choice for manufacturers across industries.

How laser cutting allows for creative freedom in manufacturing

Thanks to its precision and adaptability, laser cutting opens up endless possibilities for creative designs. From intricate engravings to custom shapes, this technology allows manufacturers to bring even the most complex ideas to life. Whether it’s signage, architectural elements, or unique prototypes, laser cutting service provides the freedom to innovate.

Efficiency and Speed in Production

Time is money in manufacturing, and laser cutting is one of the fastest ways to process materials. The laser’s ability to make precise cuts in a single pass significantly reduces production time compared to traditional methods like sawing or punching.

Why laser cutting service is faster than traditional cutting methods

Traditional cutting tools often require multiple passes or manual adjustments to achieve the desired result. In contrast, laser cutting completes the task in one go, saving both time and effort. This speed makes it ideal for meeting tight deadlines without compromising quality.

How automation in CNC laser cutting increases productivity

With CNC laser cutting, the process is fully automated. Once the design is programmed, the machine handles the cutting without constant supervision. This allows manufacturers to focus on other tasks while the laser works, increasing overall productivity.

Reduced lead times for manufacturing projects

By combining speed and precision, laser cutting shortens lead times for production. Whether it’s creating prototypes or fulfilling large orders, this technology ensures faster turnaround times, helping businesses stay competitive.

Cleaner Cuts with Minimal Waste

One of the standout benefits of laser cutting is its ability to produce incredibly smooth edges without the need for additional processing. Unlike traditional cutting methods that may leave rough or uneven edges, laser cutting uses a highly focused beam of light to achieve clean, precise cuts. This eliminates the need for sanding or polishing, saving both time and effort.

The role of focused laser beams in reducing material waste

The precision of a laser beam ensures that only the necessary material is cut, minimizing waste. Traditional methods often result in excess material being removed or damaged during the process. With laser cutting, manufacturers can optimize material usage, making it not only more efficient but also environmentally friendly.

Why cleaner cuts lead to better product quality

Smooth edges and precise cuts directly contribute to higher-quality end products. Clean cuts mean components fit together perfectly without gaps or inconsistencies. Whether it’s creating mechanical parts or decorative items, laser cutting service guarantees professional results that elevate the overall product standard.

Cost-Effectiveness for Large and Small Projects

Cost is always a key consideration in manufacturing, and CNC laser cutting offers an economical solution for both large and small-scale projects. By combining precision, speed, and automation, it significantly reduces the cost of production.

How CNC laser cutting saves costs by eliminating manual labor

Since CNC laser cutting is automated, there’s little need for manual intervention during the cutting process. This reduces labor costs, as fewer workers are required to oversee the operation. Additionally, the accuracy of the process means fewer errors, further lowering costs associated with rework or wasted materials.

Why laser cutting is cost-efficient for both prototypes and bulk production

For prototypes, laser cutting allows for quick and affordable iterations. Manufacturers can test and refine designs without spending a fortune on tooling or setup costs. For bulk production, the speed and efficiency of CNC laser cutting ensure consistent quality at a fraction of the time compared to manual methods, making it highly cost-effective for high-volume orders.

The long-term savings from reduced waste and higher accuracy

Precision cuts mean less material is wasted, and consistent results mean fewer defective products. Over time, these factors add up to significant savings. Businesses that invest in laser cutting service not only save on production costs but also benefit from better product quality, which can lead to increased customer satisfaction and loyalty.

Conclusion: Embrace the Benefits of Laser Cutting Today

From its exceptional precision to its ability to handle a wide range of materials, laser cutting has become a go-to solution for modern manufacturing. It’s fast, efficient, and versatile, making it the ideal choice for businesses that value quality and productivity.

Choosing the right laser cutting service is crucial to getting the best results. A reliable service provider ensures your projects are handled with care, accuracy, and professionalism, whether you’re creating a single prototype or managing a large production run.

If you’re looking for a way to save time, reduce waste, and achieve flawless results, consider CNC laser cutting for your next project. With its advanced technology and cost-saving benefits, laser cutting is truly the future of precision manufacturing.