Today’s small businesses face big competition. That’s why many are turning to advanced tools and technology to keep up. One of the most effective solutions is using a laser cutting service. It gives businesses the power to create high-quality parts, products, and designs quickly and affordably.

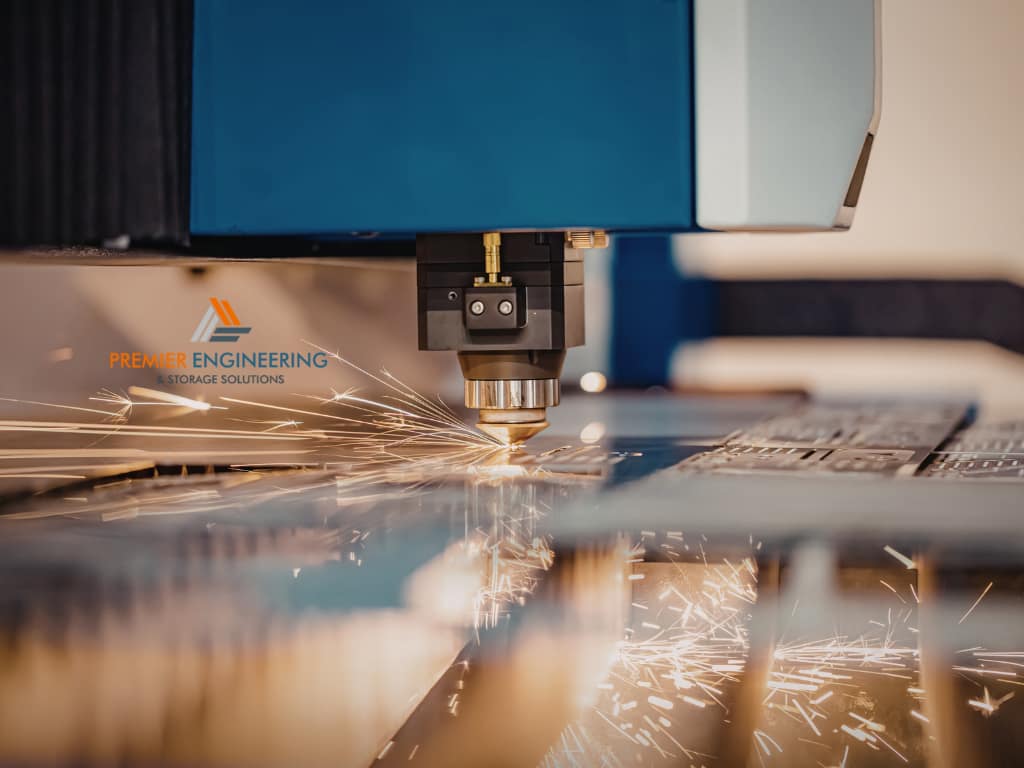

A laser cutting service uses precision and speed to produce clean, accurate cuts with very little waste. This is a huge advantage for small companies that need professional results but don’t have access to large manufacturing machines. It helps them make better products, faster — without overspending.

Why Modern Fabrication Is Worth the Investment

By embracing modern fabrication methods like laser cutting, small businesses can save time, money, and materials. The technology can handle everything from metal to acrylic and wood, making it perfect for creating both functional and decorative items.

What’s even better is that laser cutting doesn’t just make things easier — it makes them look better. Smooth edges, detailed patterns, and consistent quality mean that small businesses can now produce items that look just as professional as big brands. With the help of modern tools, creativity and precision can finally go hand in hand.

How Laser Cutting Service Makes Custom Work Easier

More Options for Custom Creations

For small businesses, flexibility matters. A laser cutting service allows them to create custom parts, signs, displays, and packaging that match their unique vision. Whether it’s a local café ordering custom menu boards or a designer making decorative panels, laser cutting makes it possible to bring creative ideas to life.

Unlike manual cutting methods, laser cutting is precise down to the millimetre. It follows digital designs perfectly, meaning there’s no guesswork or wasted material. This accuracy is ideal for start-ups and local makers who need to manage costs while maintaining high-quality standards.

Affordable and Efficient for Start-Ups

A key reason small businesses love laser cutting is its affordability. There’s no need to buy expensive machines or maintain large workshops. Instead, they can simply send their designs to a professional laser cutting service and get consistent results every time.

This approach helps businesses save money on labour and reduce waste from mistakes. It’s also faster — laser machines can complete projects in minutes that might take hours by hand. The result? High-quality, professional-grade work that helps small businesses stand out while staying on budget.

Combining Laser Cutting with CNC Sheet Metal Fabrication

How Both Processes Work Together

When small businesses want strength and precision, combining laser cutting with cnc sheet metal fabrication is the perfect solution. Laser cutting handles detailed shapes and patterns, while CNC fabrication focuses on bending, folding, and forming metal into its final shape.

Together, these two methods allow even small-scale manufacturers to create durable and attractive metal products — from shop fixtures to custom enclosures and components. The best part? They can achieve this level of quality without needing to invest in expensive machines themselves.

Why It’s a Smart Choice for Small Production

By using both laser cutting and cnc sheet metal fabrication, small businesses can create parts that fit perfectly and last longer. This combination also reduces the need for manual work, which helps speed up production times and keep costs low.

The clean cuts from laser cutting pair well with the precision bending and forming that CNC fabrication provides. It’s a reliable way for small companies to meet client demands quickly and confidently, no matter how complex the design may be.

Why CNC Punching Service and Metal Punching Services Matter

How These Services Improve Flexibility

For small manufacturers, precision and flexibility are everything. That’s where cnc punching service and Metal punching services make a big difference. These processes help create detailed shapes, holes, and slots in sheet metal — all with high accuracy and speed.

Unlike manual methods, CNC punching uses computer-controlled machines to punch exact patterns. This means every piece is consistent, no matter the quantity. Whether you’re making signage, metal panels, or product parts, cnc punching service helps small businesses produce professional results without slowing down production.

Working Together with Laser Cutting

When paired with laser cutting, punching services become even more powerful. While Metal punching services are great for repetitive shapes and speed, laser cutting handles intricate details that need smooth edges and precise finishing.

Together, they give small businesses a complete solution — speed from punching and accuracy from laser cutting. The result is better quality products with less waste, which saves time and money. It’s a smart, modern approach that helps small workshops work more efficiently.

The Benefits of Turret Punching Services for Small Production Runs

Why Turret Punching Services Are Ideal for Small Jobs

For businesses that need short production runs, turret punching services are a game-changer. This process allows multiple tools to operate in one machine, switching quickly between punches for different shapes or sizes. That means faster results without complicated setup times.

Small companies can use turret punching services to produce parts for prototypes, repairs, or limited-edition products. It’s perfect for local manufacturers who want to keep costs low while maintaining consistent quality. Because setup times are short, turret punching offers a quick turnaround — exactly what small businesses need.

Saving Time, Reducing Waste, and Improving Consistency

Every minute and every material counts in small-scale production. Turret punching services help reduce waste by using precise punches that avoid errors and material loss. This keeps production cost-effective and sustainable.

For businesses combining turret punching services with laser cutting, the advantages are even greater. They can create detailed and complex designs with minimal material use — ensuring every project stays on schedule and within budget.

How Laser Cutting Helps Boost Branding and Design

Creative Opportunities for Small Businesses

Small businesses aren’t just using laser cutting for parts — they’re using it for creativity, too. From engraved signage to custom displays, a laser cutting service can help turn a business’s brand identity into something physical and eye-catching.

With precise cuts and smooth finishes, laser cutting can create professional signage, decorative panels, or even product packaging that reflects a company’s unique style. It’s the perfect way for small shops, cafés, or design studios to make a strong first impression.

Precision That Brings Ideas to Life

Laser cutting is known for its accuracy and versatility. It can cut through metal, wood, acrylic, or plastic without damaging the surface — which means small businesses can experiment with new materials and ideas easily.

From a simple logo to intricate lettering, the precision of laser cutting ensures every design looks sharp and consistent. It helps small brands look professional, creative, and competitive, even against larger companies.

Why Partnering with a Professional Laser Cutting Service Saves Time and Money

Focus on Growth, Not Production Problems

Running a business is already demanding — managing equipment, materials, and deadlines can be stressful. That’s why outsourcing work to a trusted laser cutting service makes so much sense. Professionals handle everything from design setup to precise cutting, allowing small business owners to focus on what truly matters — growing their brand.

Partnering with experts also means consistent results. Whether it’s cnc punching service, turret punching services, or Metal punching services, professional fabricators ensure the job is done right the first time, with no costly rework.

The Smart Way to Build a Better Business

Modern fabrication technology is no longer just for large manufacturers. Small businesses can now access the same tools — laser cutting, cnc sheet metal fabrication, and punching services — without needing to buy expensive machinery.

By outsourcing these services, small companies can enjoy faster production, reduced costs, and higher-quality results. It’s a practical, stress-free way to turn ideas into real products. And in today’s fast-moving market, that kind of efficiency and precision can make all the difference.