In the fast-paced world of business, standing out is more crucial than ever. With the ever-growing demand for bespoke solutions to meet specific business needs, Perspex has emerged as a versatile solution. Perspex, often referred to as acrylic sheets, presents a myriad of possibilities, allowing businesses to convey their brand identity effectively and innovatively.

Diverse Commercial Uses of Cut-to-Size Perspex

Acrylic Sheets in Retail: One of the most apparent applications of Perspex in the business domain lies in retail. Be it a chic boutique in a bustling city or a quaint store in a suburban area, acrylic sheets have revolutionized the way products are displayed. The clear, glass-like appearance of Perspex allows for an unobstructed view of products, ensuring they capture attention. Furthermore, their lightweight nature makes them ideal for window displays and in-store presentations.

Hygiene Screens: In recent times, hygiene and safety have taken center stage in business operations. Here too, Perspex shines. With the onset of the pandemic, businesses quickly realized the need for barriers that did not disrupt customer interaction. Enter Perspex. Clear hygiene screens made from Perspex provided an effective solution, ensuring safety while maintaining the much-needed personal touch in customer interactions.

Design and Fabrication: As businesses seek to differentiate themselves in a saturated market, customized Perspex solutions have become the go-to option. Through Acrylic fabrication, businesses can achieve intricate designs, tailor-made to resonate with their brand identity. Whether it’s unique signage, brand logos, or customized decor pieces, the design and fabrication potential with Perspex is limitless.

Plastic Display Units: The advantages of using Perspex extend to the realm of exhibitions and trade shows. Customized plastic display units crafted from Perspex not only provide durability but also offer a sleek appearance. These units are lightweight, easy to transport, and can be fabricated to suit various display needs, making them a favorite for businesses participating in events and exhibitions.

Benefits of Bespoke Perspex Designs for Businesses

Brand Differentiation: In a market where many brands vie for attention, a custom Perspex design can make all the difference. It offers a unique visual appeal, setting businesses apart from competitors.

Versatility: Perspex can be molded, perspex cutting, and designed in countless ways, offering businesses the flexibility to actualize their vision.

Durability: Unlike traditional glass, Perspex doesn’t shatter easily. This means display units and other business assets crafted from Perspex tend to have a longer lifespan.

Cost-Effective: In the long run, investing in Perspex proves to be cost-effective. Given its durability, there’s less need for frequent replacements. Additionally, its lightweight nature can lead to savings in transportation and installation.

Cutting and Working with Acrylic Perspex

While the benefits and applications of Perspex in businesses are vast, understanding the nitty-gritty of working with this material is equally essential. For businesses that choose to customize or adjust their Perspex products in-house, it’s crucial to understand how to cut, drill, and handle this material effectively and safely.

How to cut acrylic perspex?

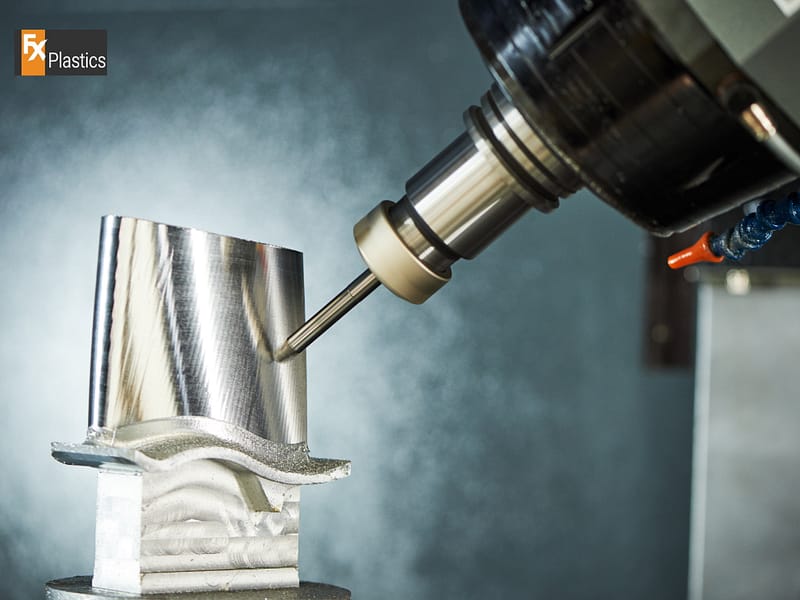

Cutting Acrylic Perspex requires precision and expertise to achieve clean and smooth edges. While it’s possible to do it yourself with the right tools and techniques, there’s always a risk of chipping, cracking, or melting the material. Choosing an expert for this task ensures professional results, minimizes material wastage, and provides peace of mind. Investing in professional services ensures that your Perspex is handled with care, expertise, and state-of-the-art equipment, delivering a finish that’s second to none.

Preparation: Before you start cutting, it’s important to remove the protective film on the Perspex sheet’s surface. This helps in achieving a cleaner cut and prevents any unwanted scratches.

Marking: Use a grease pencil or a water-soluble marker to mark the area you intend to cut. This ensures precision and reduces wastage.

Cutting Technique: For straight cuts, a table saw or circular saw is often used. For curves, a jigsaw or bandsaw can be employed. When cutting, make sure the saw blade is sharp and moves at a high speed to prevent chipping or melting the material.

What kind of blade do you use to cut Perspex?

When working with Perspex, the blade is crucial. A carbide-tipped saw blade is recommended. These blades have a greater number of teeth and are designed to produce less heat when cutting, which is essential when working with acrylics. The blade should be fine-toothed, typically with a minimum of 80 teeth for a 250mm blade, ensuring the cut is smooth and free from jagged edges.

Is perspex easy to cut and drill?

Yes, with the right tools and techniques, Perspex is relatively straightforward to cut. Its flexibility and adaptability make it a favorite for businesses that need customized designs.

Drilling Perspex: Just like cutting, drilling through Perspex requires a bit of finesse. Standard wood drill bits work well for Perspex, but it’s essential to ensure the bit is sharp. When drilling, always start slowly to prevent chipping and gradually increase the speed. It’s recommended to support the sheet on both sides to minimize vibrations.

In the world of Design and Fabrication, being adept at handling materials like Perspex can significantly enhance the outcome. With its versatility, Perspex provides an excellent canvas for businesses to bring their vision to life, but understanding the intricacies of working with it ensures that the end product is as envisioned and stands the test of time.