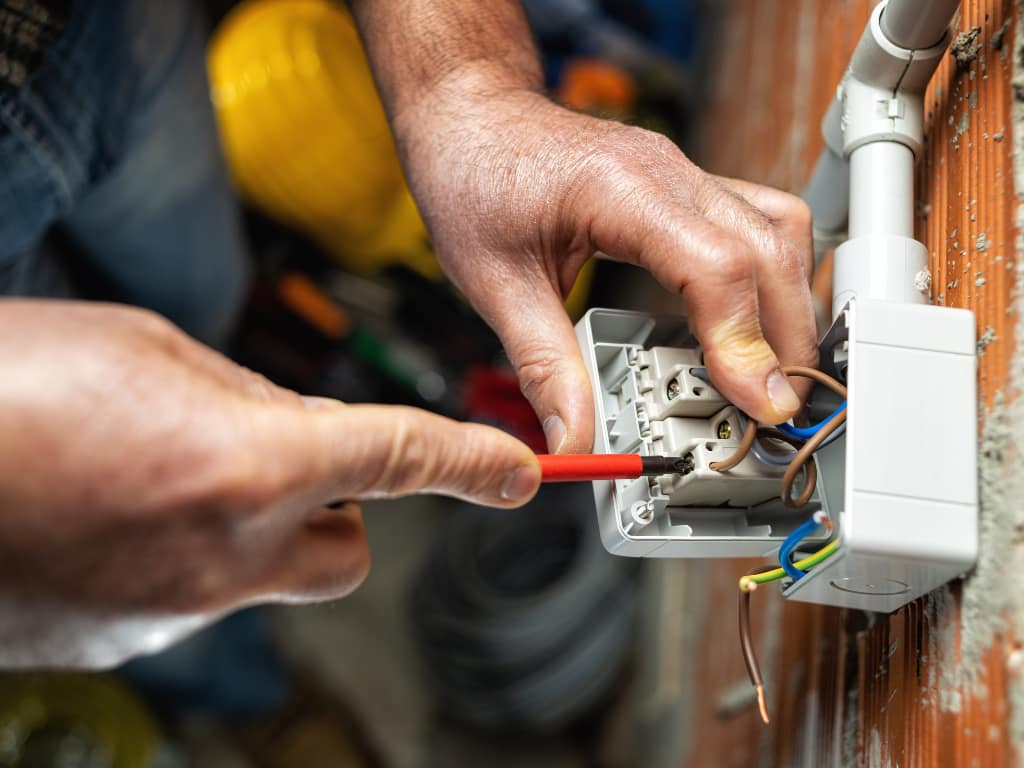

Custom electrical fit outs involve the configuration and installation of electrical systems tailored to meet the specific operational needs of a business or commercial space. Unlike standard electrical setups, custom fit outs cater to unique requirements that vary significantly across different industries such as healthcare, hospitality, or manufacturing. These customizations ensure that the electrical infrastructure not only supports the daily operations efficiently but also adheres to industry-specific safety and performance standards.

The Role of Commercial Electrician Services in Custom Fit Outs

Commercial electrician services are integral to the success of any custom electrical fit out project. Their expertise in designing, installing, and maintaining complex electrical systems is crucial for:

- Tailoring Solutions: Electricians design electrical systems that specifically match the functional requirements of the space.

- Ensuring Compliance and Safety: Professional electricians ensure that all installations comply with national and local regulations, which is critical for the safety of the premises and its occupants.

- Seamless Implementation: Experienced electricians manage the implementation of these systems, ensuring minimal disruption to ongoing operations.

Assessing Needs for Custom Electrical Installations

Identifying Unique Electrical Requirements

To effectively plan a custom electrical fit outs, it’s essential to first identify the specific electrical needs of the space. This process involves:

- Conducting Site Evaluations: Electricians perform thorough assessments of the site to understand the physical layout and existing electrical infrastructure.

- Understanding Business Operations: Gaining insights into the business operations to determine the types of machinery, equipment, and lighting needed.

- Consulting Stakeholders: Working with management and various department heads to incorporate all operational requirements into the electrical design.

Consultation and Planning with a Commercial Electrician

Consulting with a professional commercial electrician early in the planning phase is crucial for:

- Accurate Needs Assessment: Electricians can provide valuable insights into the types of installations required to support specific business activities.

- Budget Planning: Early consultations help in budgeting as electricians can provide estimates on the cost of necessary work and equipment.

- Project Timeline Development: Professional electricians will help develop a realistic timeline for the completion of the fit out, aligning with business schedules and minimizing downtime.

Designing Electrical Systems for Specialized Environments

Key Considerations in Designing Custom Electrical Systems

When designing electrical systems for specialized environments, several key factors must be considered:

- Safety: Ensuring all systems are up to code and meet safety standards to protect both personnel and property.

- Efficiency: Designing energy-efficient systems that reduce operational costs and support sustainability goals.

- Flexibility: Creating adaptable systems that can evolve with changing business needs or technological advancements.

Innovative Design Solutions for Challenging Spaces

Commercial electricians often need to innovate to overcome unique challenges presented by specialized spaces:

- Space Constraints: Developing compact, multi-functional electrical solutions for spaces with limited area.

- Harsh Environments: Designing durable systems for areas exposed to extreme conditions like high temperatures or moisture.

- High Demand Systems: Configuring systems that can handle high loads reliably for spaces like data centers or industrial manufacturing plants.

Implementation of Custom Electrical Fit Outs

Project Management for Electrical Installations

Effective project management is critical to the successful implementation of custom electrical fit outs. Best practices include:

- Timeline Management: Establishing clear timelines with specific milestones helps keep the project on track. Commercial electricians use project management tools to schedule and monitor each phase of the installation, ensuring deadlines are met.

- Resource Allocation: Proper allocation of resources, including manpower, materials, and equipment, is planned in advance. This involves ensuring that the right tools are available at the right time and that staffing is adequate to meet project demands without overspending.

- Quality Control: Implementing rigorous quality control measures at every stage of the installation process. This includes regular inspections and testing of electrical components and systems to ensure they meet both the design specifications and safety standards.

Technical Challenges and Solutions During Installation

During the installation of custom electrical fit outs, several technical challenges may arise, including:

- Complex System Integration: Integrating new electrical systems with existing infrastructure can be challenging, especially in older buildings. Solutions often involve using adaptable components that can work with both old and new technologies.

- Space Limitations: In confined spaces, managing the layout to accommodate all necessary electrical equipment without overcrowding can be difficult. Electricians often use custom-designed components and innovative installation techniques to maximize space efficiency.

- Electrical Load Management: Ensuring that the electrical system can handle the load without overloading circuits is crucial. This is addressed by conducting detailed load assessments and designing the system to distribute power evenly and safely.

Regulations and Compliance for Specialized Electrical Installations

Compliance with Local and Industry-Specific Electrical Codes

Custom electrical fit outs must comply with a range of regulatory requirements, which vary by location and industry:

- Local Building Codes: Adherence to local building codes is mandatory. These codes dictate the standards for electrical installations, including the types of materials used, installation methods, and safety measures.

- Industry-Specific Regulations: Certain industries, such as healthcare and manufacturing, have additional compliance requirements to ensure the safety and reliability of electrical installations in environments with unique hazards or operational demands.

Ensuring Safety and Efficiency Through Compliance

Compliance with electrical codes is not just a legal obligation—it also plays a critical role in ensuring the safety and efficiency of an installation:

- Safety: Compliance helps prevent risks associated with electrical fires, shocks, and other hazards, thereby protecting property and lives.

- Operational Efficiency: Electrical systems designed and installed according to code are more likely to run efficiently and with fewer interruptions, which translates to lower operational costs and reduced downtime.

- Inspections and Certifications: Regular inspections by certified inspectors are part of the compliance process. These inspections help identify and rectify potential issues before they can cause significant problems.

Maintenance and Upgrades for Custom Electrical Systems

Maintenance Strategies for Complex Electrical Installations

Maintaining custom electrical systems effectively is crucial to ensure their longevity and optimal performance. Here are some recommended strategies:

- Regular Inspections: Schedule routine inspections to identify and resolve issues before they lead to system failures. This includes checking for wear and tear, ensuring that all components meet safety standards, and verifying that the system operates efficiently.

- Preventative Maintenance: Implement a preventative maintenance program that includes tasks such as cleaning components, tightening connections, and testing system functionality. This proactive approach helps extend the life of the equipment and can prevent costly repairs and downtime.

- Training for Staff: Ensure that staff who operate and manage these systems are properly trained in basic troubleshooting and maintenance procedures. This enables quicker responses to minor issues and better communication with technicians.

Planning for Future Upgrades and Expansion

To future-proof electrical installations and ensure they can accommodate growth and technological advancements, consider the following:

- Scalability: Design electrical systems with scalability in mind. This means selecting components that can handle increased capacity and configuring installations in a way that additional elements can be integrated with minimal disruptions.

- Technological Upgrades: Stay informed about advancements in electrical technology that could enhance system performance or efficiency. Plan for periodic updates to software and hardware that can keep the system at the forefront of technology.

- Flexible Design: Incorporate flexible design principles that allow for easy modifications to the system as the needs of the business change. This includes using modular components and ensuring that additional capacity can be added without a complete system overhaul.

Conclusion

Custom electrical fit outs offer significant advantages for specialized commercial spaces, enhancing not only the functionality and safety of these environments but also their operational efficiency. Tailored solutions ensure that electrical systems precisely meet the specific needs of a facility, allowing for optimized energy management, improved safety protocols, and better overall performance.