Introduction:

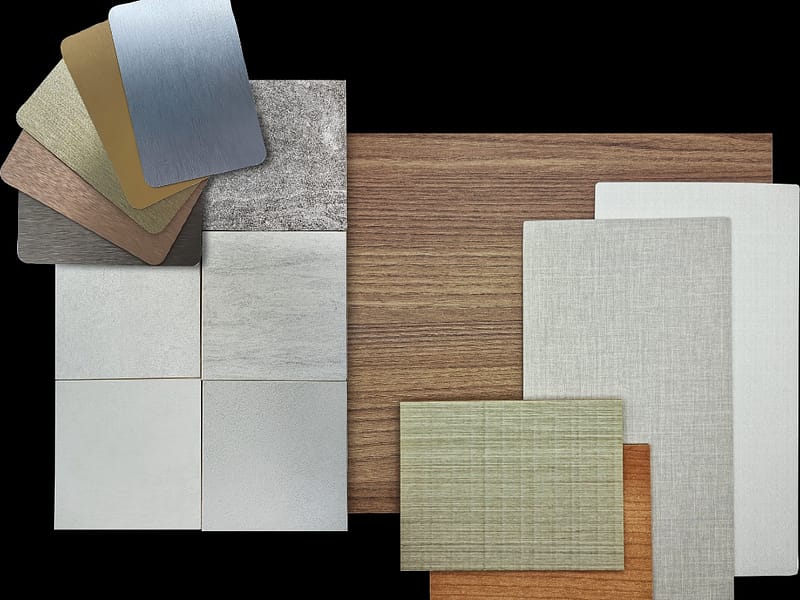

In today’s rapidly evolving interior design landscape, the materials we choose play a pivotal role in both functionality and aesthetics. Among the various options, timber veneer, laminate, and melamine stand out as popular choices, each with its unique properties and applications.

Detailed Comparison Table: Timber Veneer vs. Laminate vs. Melamine

| Feature/Aspect | Timber Veneer | Laminate | Melamine |

|---|---|---|---|

| Material Origin | Thin slices from timber logs | Multi-layer synthetic product | Resin-infused paper |

| Appearance | Natural wood grain; unique patterns | Mimics wood or other designs | Solid colors or printed patterns |

| Durability | Moderate; can be refinished | High; scratch-resistant | Moderate; surface can chip |

| Cost | Generally higher | Moderate | Generally lower |

| Maintenance | Periodic sealing/oiling | Wipe with damp cloth | Wipe with damp cloth |

| Sustainability | Biodegradable; sustainable sourcing | Less sustainable; resin-based | Uses formaldehyde; less sustainable |

| Moisture Resistance | Can warp with excessive moisture | Highly water-resistant | Can bubble with moisture |

| Heat Resistance | Moderate | High; heat-resistant | Low; can warp with excessive heat |

| Application Use | Cabinetry, furniture, wall panels | Countertops, cabinets, flooring | Shelves, cabinets, low-cost furniture |

What are the primary differences between timber veneer and laminate?

- Origin & Composition: Timber veneer is made by slicing thin sheets directly from logs of wood. These sheets showcase the natural wood grain and patterns. On the other hand, laminate is a multi-layer synthetic product. It’s created by pressing together multiple layers of paper soaked in resin, with the topmost layer typically being a printed design, often mimicking wood or other patterns.

- Appearance: Timber veneer offers a natural and unique wood appearance, which can vary depending on the type of wood and the cut. Laminate, being synthetic, can mimic various designs including wood grains, but lacks the depth and uniqueness of real wood.

- Feel: Timber veneer feels like real wood to the touch because it is real wood, albeit thin. Laminate has a more uniform and often smoother feel, and while it can visually mimic wood grain, it doesn’t truly replicate the tactile sensation of natural wood.

- Durability & Maintenance: Timber veneer requires maintenance to retain its appearance and is susceptible to dents and scratches. However, it can often be refinished. Laminate is generally more resistant to scratches, stains, and UV rays but cannot be refinished if it’s damaged.

How does the appearance and feel of melamine compare with timber veneer?

- Appearance: Melamine is typically made of paper infused with resin, pressed onto a substrate, and then sealed with a protective top layer. The design layer in melamine can be printed to look like wood or can be a solid color. Its appearance is usually more consistent and uniform compared to the natural variations of timber veneer.

- Feel: Melamine has a smooth and consistent texture. Unlike timber veneer, which has the tactile feel of the wood grain it’s sliced from, melamine lacks the depth and texture of real wood.

Which is more durable: timber veneer, laminate, or melamine?

- Timber Veneer: Moderate durability. It can be susceptible to dents, scratches, and moisture but can often be refinished to restore its appearance.

- Laminate: High durability. It’s resistant to scratches, stains, and UV rays. However, if the top layer gets damaged, it cannot be refinished.

- Melamine: Moderate durability. While it’s resistant to many everyday wear and tear factors, its surface can chip or get damaged, especially on the edges, and it can’t be refinished like wood.

Pros and Cons of Each Material:

Timber Veneer:

- Advantages: Offers a rich, natural look, showcasing the innate beauty of wood. It can be refinished if damaged and is versatile for various applications, including upscale furniture and intricate wood paneling. Timber veneer sheets, made from genuine timber logs, promise an authentic wood experience.

- Drawbacks: Requires more maintenance and can be more expensive. Susceptible to dents, scratches, and moisture, though refinishing can restore its beauty.

Laminate:

- Advantages: Durable, resistant to scratches, stains, and UV rays. Offers a variety of design choices, making it versatile for many applications. The multi-layered structure gives it strength.

- Drawbacks: Synthetic in nature, so while it can mimic the look of wood, it doesn’t quite replicate the feel or depth. Cannot be refinished if damaged.

Melamine:

- Advantages: Cost-effective and easy to maintain. With its smooth finish, it’s a popular choice for shelves, cabinets, and some furniture pieces.

- Drawbacks: The surface can chip, especially along the edges. It’s also less heat resistant and can warp if exposed to high temperatures.

Conclusion:

Choosing the right material for a project involves weighing aesthetics, functionality, cost, and sustainability. While timber veneer provides a natural and premium finish, laminate and melamine offer durable and cost-effective alternatives. By understanding the distinct features of each, one can make an informed decision tailored to specific project needs and desired outcomes.