Introduction

Navigating through the options in the plastic materials market is crucial for project success. Acrylic sheets offer a clear advantage in certain applications, but how do they stack up against other plastics like polycarbonate and PVC (Polyvinyl Chloride)?

This comparison will provide detailed insights to help you make an informed choice based on your specific needs.

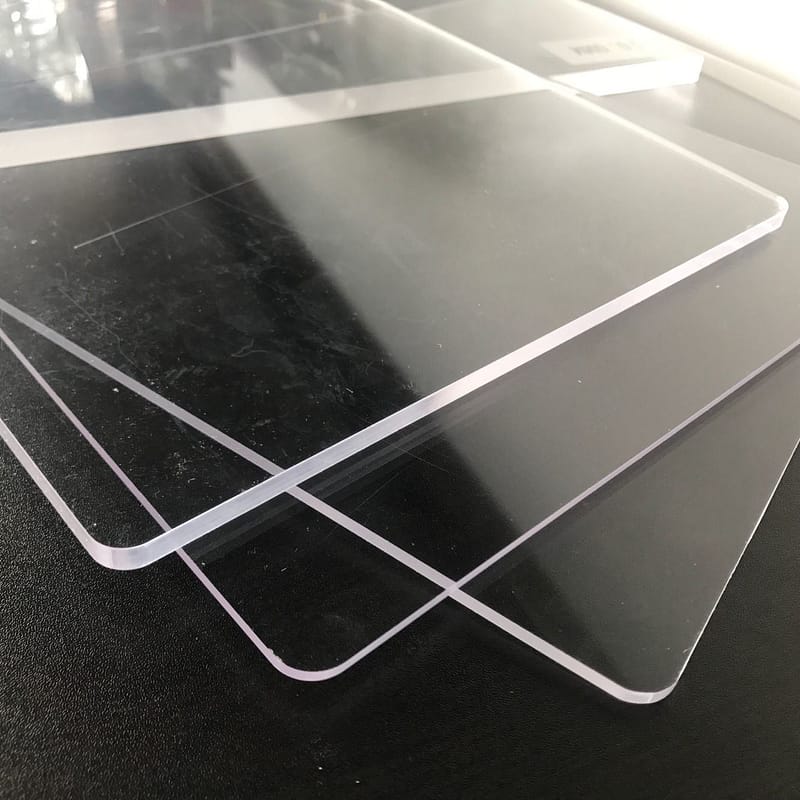

Understanding Acrylic Sheets

Acrylic sheets, or perspex, known for their glass-like clarity and excellent weather resistance, are favored for a variety of applications. They are particularly noted for:

- Optical Clarity: Superior light transmission for a clear view.

- Durability: Resistant to weathering and UV light, maintaining clarity over time.

- Workability: Easily shaped, cut, and molded, making them versatile for numerous applications.

Common uses for acrylic sheets include signage, retail displays, and architectural features where transparency and aesthetics are paramount.

Acrylic vs. Polycarbonate and PVC: A Detailed Comparison

Polycarbonate Characteristics:

- Impact Resistance: Much higher than acrylic, ideal for security and safety applications.

- UV Resistance: Requires UV stabilizers to prevent long-term yellowing.

- Flexibility: More flexible than acrylic, less likely to crack under impact.

Acrylic vs. PVC (Polyvinyl Chloride)

To compare Acrylic with PVC, let’s look at their properties side by side:

| Property | Acrylic | PVC |

|---|---|---|

| Clarity | High optical clarity, transparent | Often opaque, less clarity |

| Durability | Resistant to UV light and weathering | Durable but can degrade with UV exposure |

| Flexibility | Rigid, can crack under impact | Available in rigid and flexible forms |

| Workability | Easy to cut, drill, and shape | Easy to work with, weldable |

| Environmental Impact | Recyclable, more eco-friendly | Contains chlorine, harder to recycle |

Environmental Considerations:

- Acrylic is considered more environmentally friendly and easier to recycle than PVC.

- PVC’s production and disposal can be problematic due to chlorine content and potential release of harmful chemicals.

Other Plastics in Comparison

When evaluating acrylic sheets for your project, it’s important to compare them to other plastics on the market. Each type of plastic offers distinct benefits for different applications:

PETG (Polyethylene Terephthalate Glycol)

- Durability: Offers good impact resistance, not as brittle as acrylic.

- Thermoforming Capabilities: Can be thermoformed without pre-drying, beneficial for complex shapes.

ABS (Acrylonitrile Butadiene Styrene)

- Toughness: Known for its toughness and impact resistance.

- Machinability: Easy to machine and fabricate, suitable for industrial parts.

HDPE (High-Density Polyethylene)

- Moisture Resistance: Highly resistant to water, making it ideal for outdoor applications.

- Chemical Resistance: Stands up well to many chemicals, useful for storage containers and pipework.

Application Suitability

Choosing the right plastic for your application involves matching the material properties to your project’s specific needs:

- Project Requirements: Consider the physical demands of your project. Does it need to be impact-resistant, flexible, or withstand certain temperatures?

- Aesthetic Needs: Determine if the clarity and finish of acrylic are necessary, or if the application allows for more opaque materials like HDPE or ABS.

Cost-Benefit Analysis

When selecting a plastic, it’s crucial to balance material costs against performance:

- Material Cost: Acrylic is generally more expensive than plastics like HDPE and ABS, but it offers a premium finish and clarity.

- Performance: If the performance requirements of your application can be met with a less expensive material, it may be a more cost-effective choice.

Price and Performance Balance

Here’s a look at how acrylic stacks up in terms of price and performance:

| Plastic Type | Price Point | Performance | Best Used For |

|---|---|---|---|

| Acrylic | Higher | Premium clarity, UV resistance | Displays, windows |

| PETG | Moderate | Good durability, easy to form | Food containers, medical devices |

| ABS | Lower | Tough, impact-resistant | Automotive parts, protective gear |

| HDPE | Lower | Moisture and chemical resistance | Outdoor applications, piping |

What to do next?

For a successful project, carefully consider the material selection. Consult with experts and suppliers to explore the best plastic options that meet both your performance requirements and budget. Whether it’s the clarity of acrylic or the toughness of ABS, ensure you choose the right material for your project’s specific needs.