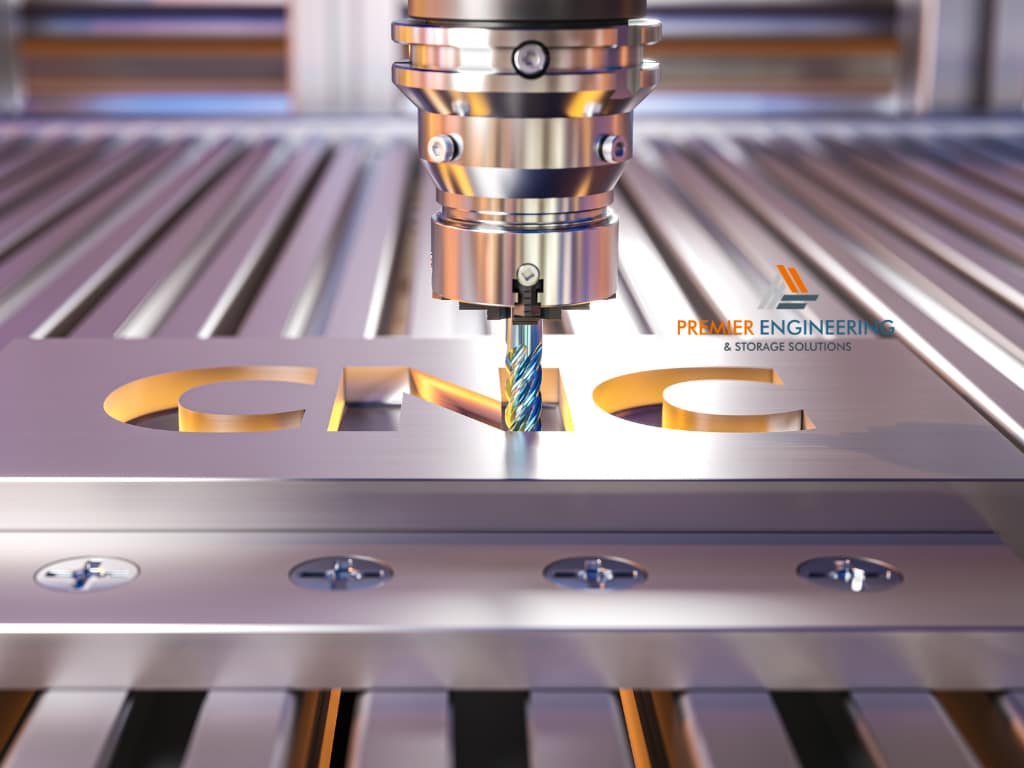

A cnc punching service is a modern method used to cut, punch, and shape metal sheets with incredible accuracy. Instead of relying on manual tools, this process uses computer-controlled machines that follow precise digital designs. The result is clean, consistent, and repeatable patterns, holes, or shapes that fit perfectly into a larger project.

These machines use programmed instructions to guide the punching heads, allowing them to process metal sheets quickly and efficiently. Because everything is automated, there’s less room for error. Whether it’s for industrial machinery, construction panels, or decorative metalwork, CNC punching delivers high-quality results every time.

Why Businesses Use CNC Punching

Companies in manufacturing and construction love cnc punching service because it combines speed, affordability, and precision. It’s ideal for creating large batches of parts without wasting materials. Since the entire process is controlled by computer software, every piece produced is identical — which helps maintain consistency across projects.

Another major benefit is cost-effectiveness. Compared to traditional cutting or drilling methods, CNC punching is faster and produces less scrap material. This means you save on both time and resources while getting top-tier results suitable for large-scale production or custom metal designs.

How Turret Punching Services Work in Modern Fabrication

What Is Turret Punching?

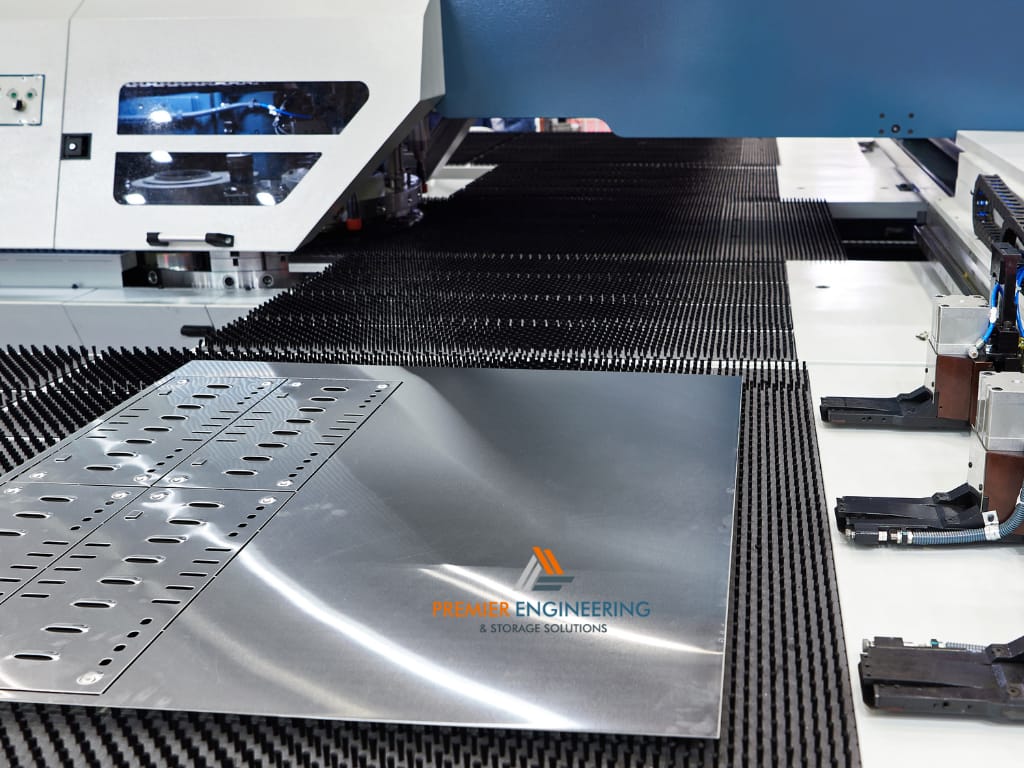

Turret punching services are a big part of modern metal fabrication. A turret punch is a machine with a rotating “turret” that holds different punching tools, each designed for a specific shape or size. As the machine works, it automatically selects the right tool and applies force to cut or stamp the metal.

This setup allows the machine to make multiple designs — from round holes and slots to custom cutouts — all in one go. It’s a fast, efficient method used in industries that need high precision, such as electronics, construction, and automotive manufacturing.

Why Turret Punching Is So Efficient

The main advantage of turret punching services is their speed and flexibility. With multiple tools loaded into one machine, there’s no need to stop and switch parts between processes. Everything happens in a single automated cycle.

This efficiency not only saves time but also reduces waste. Because the machine is computer-controlled, every punch is accurate to the millimetre. This makes turret punching perfect for creating complex components in bulk — especially when a project requires tight tolerances and detailed patterns.

Metal Punching Services for Manufacturing Efficiency

How Metal Punching Improves Production

Metal punching services are essential for modern manufacturing. They help businesses produce large quantities of metal parts quickly while maintaining the same level of quality across every piece. The process is perfect for creating panels, enclosures, and brackets that are used in construction, machinery, and consumer products.

With Metal punching services, you can rely on automation to handle repetitive tasks accurately. These machines are designed to follow detailed plans, cutting through metal with speed and precision. The result? Clean edges, perfect shapes, and parts that fit perfectly into any assembly.

Saving Time and Money with Automation

For manufacturers, time equals money. Metal punching services help reduce manual labour while speeding up production times. Since the machines can run multiple shifts with minimal downtime, you get consistent output without delays.

Another advantage is material savings. Automated punching minimises scrap and ensures every sheet of metal is used efficiently. This leads to lower costs and higher productivity — a win-win for businesses that need high-quality components at competitive prices.

The Role of CNC Punching in Construction and Architecture

CNC Punching in Building Design

The cnc punching service plays an important role in both modern construction and architectural design. It allows builders and designers to create precise, functional, and decorative metal components that improve the look and performance of buildings. From facade panels and ventilation grilles to stair treads and ceiling features, punched metal adds both style and strength.

Because the process is so accurate, architects can experiment with creative patterns and custom shapes without worrying about uneven cuts. Whether it’s for office buildings, shopping centres, or home designs, CNC punching helps transform basic metal sheets into durable, eye-catching structures.

Why the Construction Industry Relies on CNC Punching

The construction industry values cnc punching service for its ability to produce consistent results on tight schedules. Builders often need custom panels or fittings that must align perfectly — and CNC technology delivers exactly that. It’s also efficient for large projects, helping reduce manual labour while maintaining superior quality.

CNC-punched parts are also easier to install since they’re pre-cut to precise measurements. This accuracy means faster assembly on-site and fewer adjustments during installation, saving both time and cost.

Combining Metal Bending Press with CNC Punching for Custom Projects

Stronger, Customised Metal Components

When a metal bending press is combined with cnc punching service, the result is perfectly shaped, ready-to-use metal components. After the punching process, the bending press takes over to form panels, brackets, doors, or enclosures into their final shape. This combination is essential for creating parts that not only look professional but also perform reliably in demanding environments.

Using both processes together gives manufacturers more flexibility. You can bend punched sheets into custom angles or curves without affecting the integrity of the metal. This makes it ideal for complex projects that require durable, accurate, and polished results.

Where to Get Reliable Fabrication Services

If you’re looking for a professional team that offers complete fabrication solutions, Premier Engineering & Storage Solutions is a trusted name in the industry. They provide laser cutting, cnc punching, turret punching services, Metal punching services, and advanced Machining for high-quality metal components.

In addition to these services, they also manufacture Shelving Units and Storage Cabinets — perfect for industrial, warehouse, and commercial applications. By working with Premier Engineering & Storage Solutions, businesses can save time and costs by getting everything done in one place, from design and cutting to bending and finishing.

Their commitment to precision and quality ensures that every component meets the highest standards. Whether you’re in manufacturing or construction, partnering with an experienced team like Premier Engineering & Storage Solutions helps bring your metal projects to life with efficiency and accuracy.

Laser Cutting and Laser Cutting Service: Adding Precision to the Process

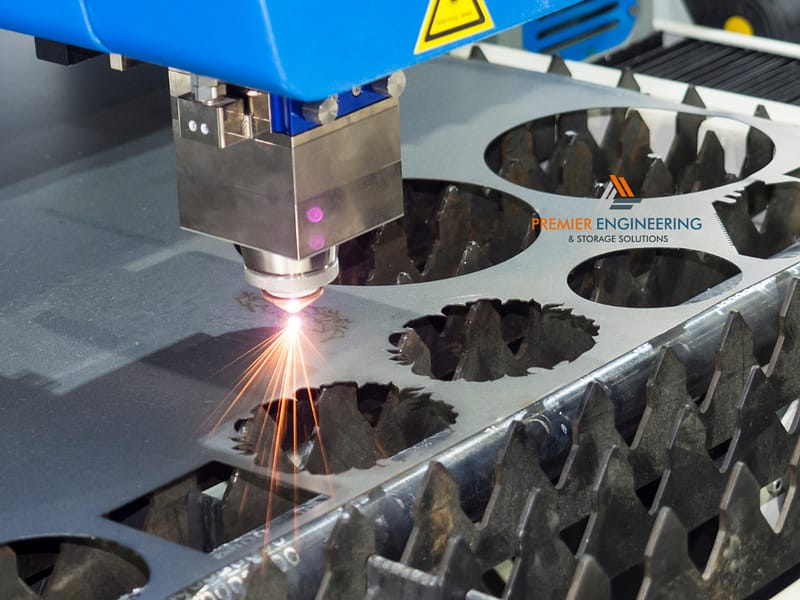

Why Laser Cutting Complements CNC Punching

Laser cutting is another vital process that works hand-in-hand with CNC punching. While punching is great for high-volume parts with standard shapes, laser cutting is ideal for creating intricate details and smooth edges. Together, these processes deliver the perfect balance of speed, precision, and design flexibility.

A laser cutting service can handle delicate patterns or sharp corners that punching tools may not reach. This allows for greater creativity in manufacturing and architecture — from fine logos and text engraving to detailed decorative elements.

A Perfect Match for High-Quality Finishes

By combining laser cutting service and CNC punching, fabricators can produce metal parts with flawless finishes. The process also minimises the need for post-production work such as grinding or smoothing. This combination is particularly useful for businesses that need a polished look without compromising on strength or durability.

Whether you’re producing metal furniture, construction panels, or industrial parts, using both techniques ensures high-quality, professional results every time.

Choosing the Right CNC Punching Service for Your Next Project

How to Find the Best Fabrication Partner

When choosing a cnc punching service provider, look for a company that offers experience, precision, and flexibility. Check if they have up-to-date machines capable of performing turret punching services, Metal punching services, and laser cutting service under one roof. This ensures you get consistent results from start to finish.

It’s also important to work with professionals who understand your project requirements. The best providers take time to review your plans, recommend the most suitable methods, and ensure every component meets your specifications.

Making the Most of Modern Fabrication

A good fabrication partner can handle more than just punching — they can manage the entire production process, including metal bending press work and final finishing. By choosing a reliable cnc punching service, you’ll get precise, durable, and cost-effective parts that enhance both your manufacturing and construction projects.

From large-scale production runs to custom-built designs, modern metal fabrication services help you save time, reduce waste, and achieve a flawless finish. Investing in professional punching and cutting services is one of the smartest moves any business can make when quality and efficiency matter most.