CNC cutting services use computer-controlled machines to cut materials with high precision. “CNC” stands for “Computer Numerical Control,” meaning the machine follows exact digital designs to create perfect cuts. These machines can handle a variety of materials such as metal, wood, and Perspex, making them ideal for projects like Perspex Cutting Sydney. Many industries rely on CNC cutting because it ensures accurate and consistent results, whether for large production runs or custom one-off projects.

CNC laser cutting offer several advantages over traditional methods like manual sawing. With CNC saw cutting, the process is automated and much faster, reducing the time needed to complete a job. Additionally, CNC machines are far more accurate, resulting in cleaner and more precise cuts. This means less material is wasted, and the final product looks polished and professional. For materials that need an even smoother finish, Diamond Polishing can be applied to enhance the end result. Whether you’re cutting wood, metal, or Perspex, CNC cutting guarantees better quality and consistency every time.

How CNC Cutting Services Improve Efficiency

Faster Production Times with CNC Cutting Services

One of the biggest benefits of using CNC cutting services is their remarkable speed. Unlike manual cutting, which can be slow and labour-intensive, CNC machines work efficiently and consistently. Once a design is programmed into the machine, it performs the cuts automatically with minimal human intervention. This automation significantly reduces the time needed to produce each piece, especially when compared to the manual process that requires constant attention and adjustments.

Whether you’re working with simple shapes or complex designs, CNC machines can handle large production volumes without compromising on quality. This is particularly advantageous for projects that demand a high number of precise cuts in a short amount of time. Additionally, CNC cutting services allow for faster turnaround times on custom orders, making it ideal for businesses that need to meet tight deadlines. The combination of speed, accuracy, and reduced labour makes CNC cutting a superior choice for both small-scale projects and mass production runs.

Consistency and Precision Every Time

CNC cutting services also ensure that every cut is exactly the same. This is especially important when you need identical parts or components. Since the machine follows a digital design, there’s no chance of human error. The precision is so high that even intricate patterns can be cut with ease. Whether you need clean lines or complex designs, CNC cutting guarantees perfect results.

Comparing CNC Saw Cutting and Traditional Sawing

What Is CNC Saw Cutting?

CNC saw cutting is an advanced cutting method where a computer-controlled saw is used to cut through a variety of materials with high precision. Unlike traditional manual sawing, which relies on the skill and accuracy of the operator, CNC saw cutting is guided by a pre-programmed digital design. This design provides the machine with exact instructions on how to make the cuts, ensuring that each cut is identical and free of human error. Because the saw is automated, the cuts are not only more precise but also more consistent, even across large production runs.

One of the standout advantages of CNC saw cutting is its ability to handle a wide range of materials. From softwoods and hardwoods to metals like aluminium and steel, and even acrylic materials such as Perspex, CNC saw cutting can manage them all with ease. This versatility makes it a valuable tool across industries such as construction, manufacturing, and custom fabrication.

The key benefit lies in the machine’s ability to follow precise instructions with minimal deviation, reducing the possibility of mistakes that are common in manual cutting. This results in cleaner cuts, less material wastage, and a more efficient overall process. CNC saw cutting also allows for complex designs that would be difficult to achieve manually, giving businesses and designers more freedom to experiment with intricate shapes and patterns without sacrificing accuracy.

Why CNC Saw Cutting Is More Accurate

CNC saw cutting is much more accurate than traditional sawing. Manual sawing can lead to uneven edges and mistakes, especially if you’re cutting complex shapes. CNC saw cutting, on the other hand, is guided by a computer, ensuring that each cut is clean and exact. This is why CNC saw cutting is often used for projects where precision is critical, like in furniture making or Perspex Cutting Sydney.

The Role of Diamond Polishing in CNC Cutting

How Diamond Polishing Enhances CNC Cutting Results

Diamond polishing is a process used to smooth and polish the edges of materials after they’ve been cut. When combined with CNC cutting services, it enhances the overall finish, especially for materials like glass or Perspex. Diamond polishing removes rough edges and gives the product a polished, professional look.

Why Combine CNC Cutting and Diamond Polishing?

Combining CNC cutting and diamond polishing ensures that the final product is not only precise but also smooth and polished. This is especially useful for products that will be on display, like signage or furniture. Diamond polishing adds a finishing touch, making the cut edges look refined and clean. Together, CNC cutting and diamond polishing create high-quality results that stand out.

Perspex Cutting Sydney: Why CNC Laser Cutting Is Best

What Is Perspex Cutting Sydney?

Perspex cutting is the process of cutting acrylic sheets, also known as Perspex, into different shapes and sizes. Perspex Cutting Sydney services use advanced CNC machines to ensure precise and smooth cuts. Whether it’s for signs, displays, or other custom projects, CNC cutting services in Sydney are known for delivering high-quality results. These machines are perfect for Perspex because they cut cleanly without cracking or chipping the material.

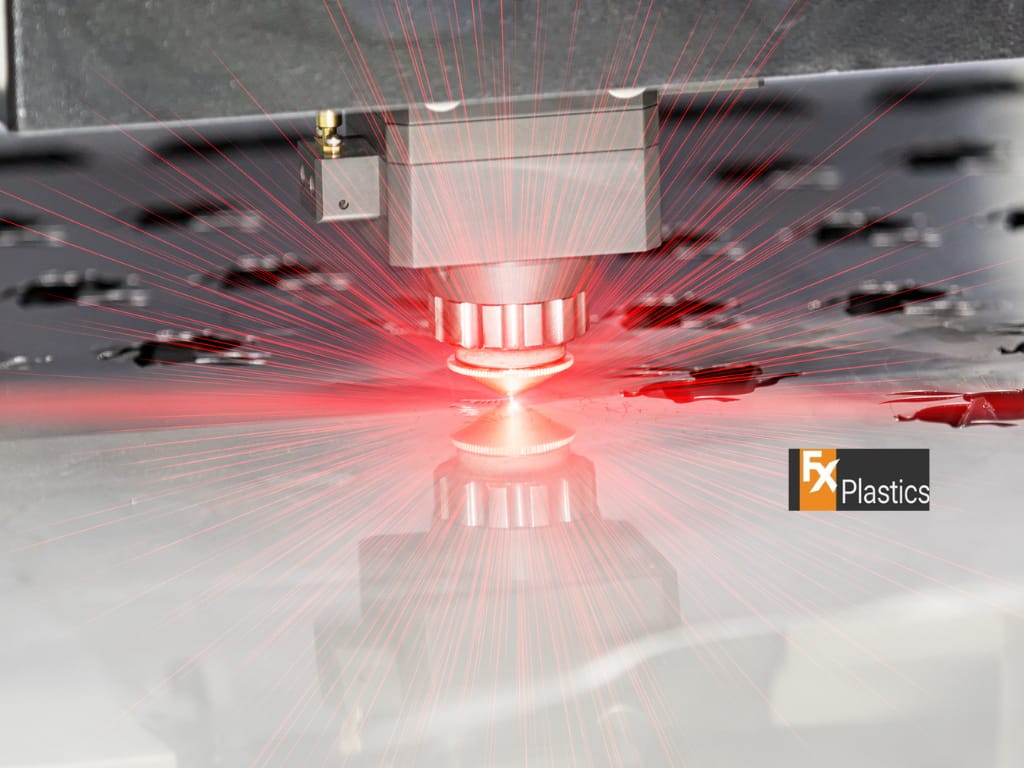

How CNC Laser Cutting Makes Perspex Cutting Easier

CNC laser cutting makes Perspex Cutting Sydney more efficient. The laser cuts through the acrylic with ease, providing smooth and sharp edges. It eliminates the roughness you might get from manual cutting methods. CNC laser cutting is also highly accurate, meaning you can achieve complex shapes with minimal effort. Plus, there’s less waste, as the precision of the laser ensures only the material needed for the design is cut.

Environmental Benefits of CNC Cutting Services

Less Waste with CNC Cutting Services

One of the biggest advantages of CNC cutting services is how much less waste they produce. Traditional cutting methods often result in a lot of leftover material that can’t be reused. With CNC cutting, the machine follows a precise design, using only the exact amount of material needed. This not only saves resources but also reduces the environmental impact by cutting down on waste.

Energy-Efficient Cutting Solutions

CNC machines are also more energy-efficient than older technologies. Because they work faster and more accurately, they use less energy overall. Traditional methods often involve multiple cuts or corrections, wasting both time and power. CNC cutting services get it right the first time, saving energy in the process.

Cost Advantages of CNC Saw Cutting and Laser Cutting

Lower Costs in the Long Run

Both CNC saw cutting and laser cutting may seem expensive at first, but they offer cost savings in the long run. The main reason is that these methods reduce errors and minimise wasted material. With manual cutting, mistakes are more common, and fixing them can cost both time and money. CNC cutting ensures every cut is perfect, lowering the chances of needing to redo a job.

How CNC Cutting Services Save Time and Money

CNC cutting services also save time, which ultimately saves money. Since CNC machines work quickly and accurately, projects are completed faster than with traditional methods. This means less time spent on labour and fewer materials wasted due to mistakes. In the long run, businesses can save both time and money by choosing CNC cutting services over manual methods.

Why Choose CNC Cutting Services in Sydney?

Final Thoughts on CNC Cutting

CNC cutting services offer many advantages over traditional cutting methods. They provide faster, more accurate cuts, reduce material waste, and are more energy-efficient. Whether you’re working with metals, wood, or acrylic, CNC machines ensure every project is completed with precision. For anyone looking for high-quality cuts, especially for Perspex Cutting Sydney, CNC is the way to go.

Finding the Right CNC Cutting Service in Sydney

If you’re based in Sydney and need precision cutting, CNC cutting services are your best option. Whether it’s for Perspex Cutting Sydney or other materials, CNC cutting ensures you get clean, accurate results every time. Look for a reliable CNC service provider that can handle your specific needs, whether it’s CNC saw cutting or adding a polished finish with Diamond Polishing.