In engineering manufacturing and fabrication capabilities, quality control is the key to making sure every product meets the required specifications. This means checking every stage of production, from the first design to the final inspection, to ensure nothing is missed.

When quality control is strong, the products are consistent, reliable, and safe to use. Customers can trust that what they receive will perform as expected, whether it’s a small component or a large industrial structure.

Why it’s essential for safety and long-term reliability

In many industries, poor quality can lead to serious safety risks. Faulty parts might fail under stress, causing accidents or expensive damage. By applying strict quality control in engineering manufacturing and fabrication capabilities, these risks are greatly reduced.

It also improves long-term reliability. Well-made parts last longer, perform better, and reduce the need for repairs or replacements. This not only saves money but also builds trust between suppliers and clients.

The Role of Precision Tools Like laser cutting in Quality Control

How laser cutting improves consistency

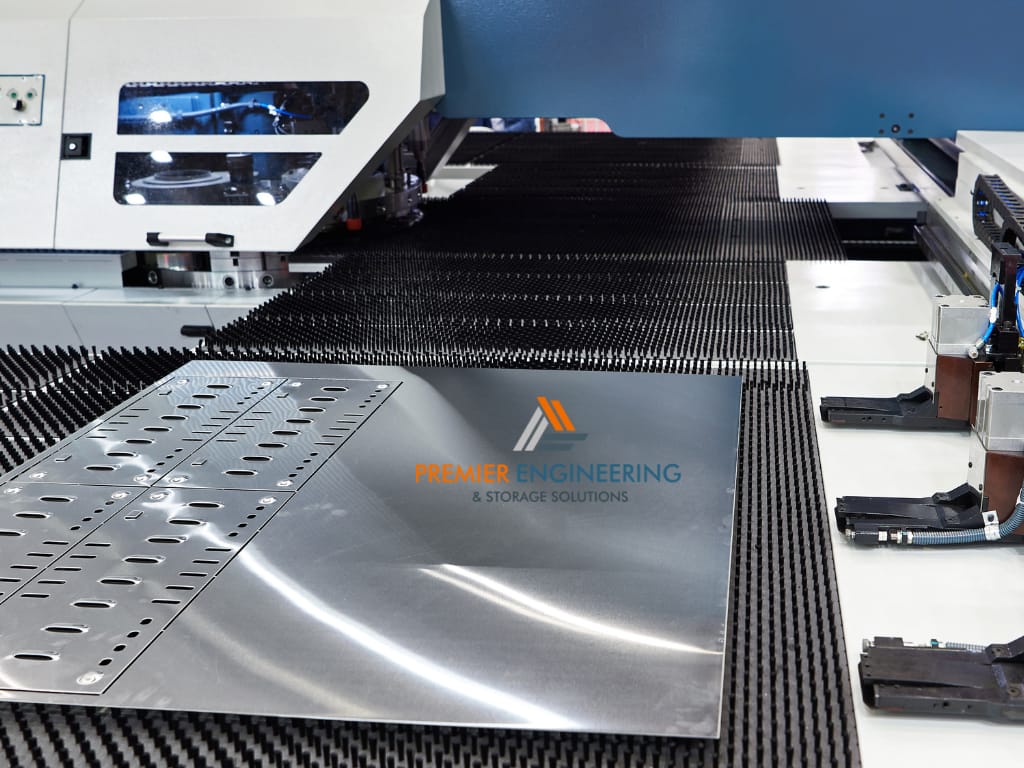

Modern manufacturing depends heavily on precision tools, and laser cutting is one of the most important. It uses a focused beam to make clean, accurate cuts in different materials. Because the process is computer-controlled, it delivers the same result every time, which is crucial for maintaining quality.

By using laser cutting, manufacturers can create parts that fit together perfectly, reducing errors and waste. This accuracy means less rework and faster production times.

Reducing waste and improving efficiency

Quality control isn’t just about the finished product—it’s also about making production more efficient. With laser cutting, material waste is minimised because every cut is planned and precise. This lowers costs and helps keep projects on schedule.

In engineering manufacturing and fabrication capabilities, tools like these are not optional—they are essential for delivering top-quality products that meet customer expectations every time.

How a laser cutting service Maintains High Standards

Precision from start to finish

A professional laser cutting service doesn’t just make quick cuts—it ensures every project is handled with care and accuracy. From the moment the design is loaded into the system, the machine follows exact measurements so every piece is identical. This kind of precision is key to meeting strict quality control requirements.

By working with a trusted laser cutting service, businesses can be confident that their parts will fit perfectly, whether they are for construction, automotive, or custom fabrication projects.

Quality checks at every step

Top service providers also perform quality checks after cutting. They inspect the dimensions, smoothness of edges, and material finish to ensure everything meets the client’s standards. This step helps maintain the high quality that is expected in engineering manufacturing and fabrication capabilities.

Using an industrial steel cutting machine for Consistent Results

Why large-scale projects rely on them

An industrial steel cutting machine is designed for handling big jobs with heavy materials. These machines use advanced technology to cut through thick steel with speed and accuracy, making them ideal for large-scale production runs.

In engineering manufacturing and fabrication capabilities, having consistent results is essential—one wrong cut can cause delays and cost money. These machines help avoid that risk.

Improving speed and reducing errors

Because they are computer-controlled, industrial steel cutting machine setups can repeat the same cut hundreds or even thousands of times without variation. This ensures parts are uniform, which is crucial for building structures or machinery that must fit together perfectly.

Ensuring Accuracy in cnc stainless steel Projects

Why CNC technology is important

cnc stainless steel work involves computer-controlled machines that shape and cut stainless steel to exact measurements. This process removes the chance of human error and ensures every part is consistent.

For projects that demand high durability and precision, CNC machining is the best choice. It allows for intricate designs and flawless execution, which is vital in engineering manufacturing and fabrication capabilities.

Meeting high-quality expectations

CNC technology is also capable of working on multiple parts at once, which speeds up production without sacrificing quality. In industries where deadlines are tight, this balance between speed and accuracy is a huge advantage.

Common Quality Control Methods in engineering manufacturing and fabrication capabilities

Inspections and testing

In engineering manufacturing and fabrication capabilities, inspections are done at different stages of production. This includes measuring parts, checking for defects, and testing strength or durability. These steps ensure each product meets the required standards.

Compliance and certifications

Many industries require manufacturers to meet specific certifications before their products can be used. Quality control teams make sure every project follows these regulations. This protects both the manufacturer and the customer from costly issues later.

How Quality Control Improves Efficiency and Customer Satisfaction

Saving time and reducing waste

Strong quality control processes prevent mistakes before they happen. This means less rework, fewer rejected parts, and faster delivery times. In engineering manufacturing and fabrication capabilities, this efficiency can lead to significant cost savings.

Building customer trust

When customers receive high-quality products that perform as promised, they’re more likely to return for future orders. Consistency builds trust, and trust is one of the most valuable outcomes of investing in quality control—whether it involves laser cutting, cnc stainless steel, or any other specialised process.