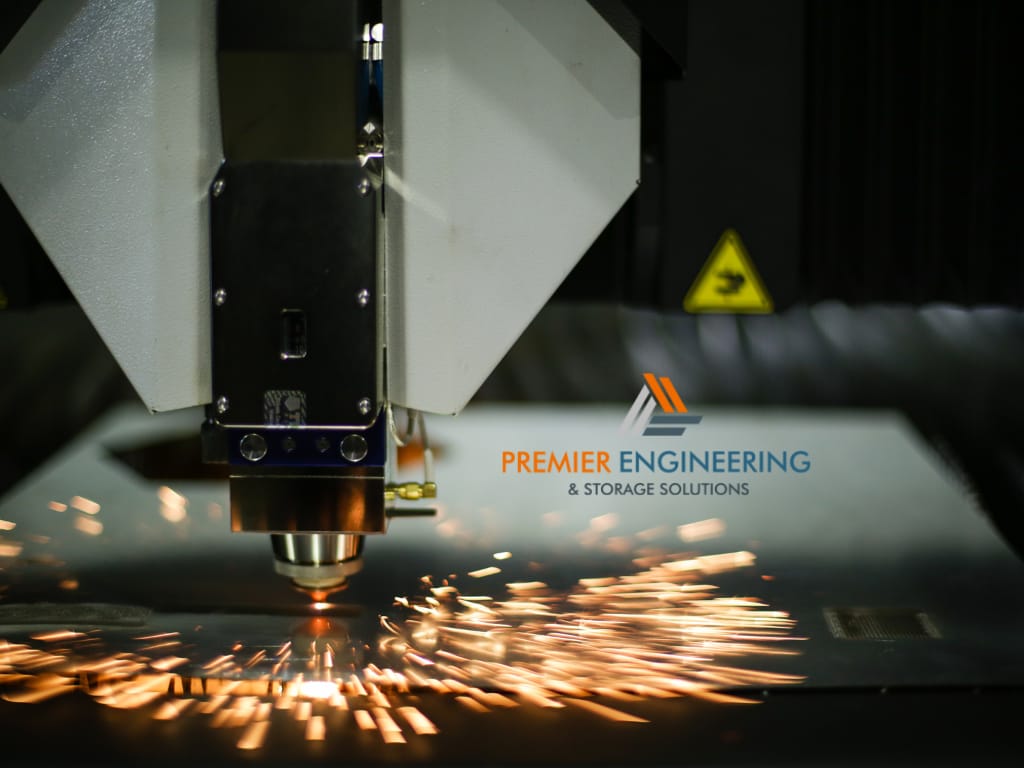

Laser cutting is a modern and highly efficient method used for cutting materials with precision. It involves using a focused laser beam to cut, engrave, or shape materials like metals, plastics, and wood. Whether you need steel metal cutting for industrial projects or detailed designs for custom work, laser cutting offers unmatched accuracy.

What Is Laser Cutting?

Laser cutting is a process that uses concentrated light beams to cut through or engrave materials. The laser’s heat melts, burns, or vaporizes the material, leaving smooth and precise edges. This makes it an ideal choice for intricate designs and challenging materials. For tasks requiring high precision, many industries prefer steel laser cutting service.

Why Is Laser Cutting So Popular?

Laser cutting has become popular because of its versatility and efficiency. It works with various materials, from delicate plastics to tough metals like steel. Unlike traditional methods, laser cutting provides cleaner cuts, minimizes waste, and reduces the need for additional finishing. Its precision is especially valuable for industries needing detailed work, such as CNC cutting services or steel metal cutting.

How Does It Compare to Other Methods Like CNC Cutting Services?

While cnc cutting services use mechanical tools to cut materials, laser cutting relies on heat and light. Laser cutting is faster, more precise, and better suited for complex shapes and fine details. CNC cutting services, on the other hand, excel at tasks like milling and drilling. When deciding between the two, consider the material, design complexity, and level of precision required.

CO2 Laser Cutting: Perfect for Non-Metals and More

CO2 laser cutting is one of the most widely used methods for cutting non-metals and thinner materials. It uses a carbon dioxide laser, making it highly effective for projects like engraving or cutting wood, acrylic, and fabric.

What Is CO2 Laser Cutting?

CO2 laser cutting works by using a gas mixture (primarily carbon dioxide) to produce a powerful infrared laser beam. This method is best suited for non-metal materials because of its efficiency and smooth cutting results. While not the primary choice for steel metal cutting, it excels in other areas.

Applications of CO2 Laser Cutting in Industries

CO2 laser cutting is widely used in industries such as packaging, signage, and textiles. It’s perfect for creating intricate designs, engraving logos, and cutting through soft materials. Though not typically used for steel laser cutting services, it plays a significant role in producing detailed non-metal components.

Can It Be Used for Steel Metal Cutting?

CO2 laser cutting is not commonly used for steel metal cutting due to its limitations with thicker and tougher materials. However, it can handle thin sheets of steel when paired with an assist gas, such as oxygen. For heavy-duty steel cutting tasks, fiber laser cutting or CNC cutting services are often more effective.

Fiber Laser Cutting: The Modern Choice for Metals

Fiber laser cutting is a state-of-the-art method ideal for cutting metals with high precision and speed. It’s a go-to choice for steel laser cutting services in industries requiring top-quality results.

Why Is Fiber Laser Cutting Ideal for Steel Laser Cutting Services?

Fiber lasers are designed specifically for cutting metals, including stainless steel, aluminum, and brass. The concentrated energy of the laser makes it perfect for steel metal cutting, delivering clean, smooth edges without damaging the material. Steel laser cutting services often rely on fiber lasers for their efficiency and accuracy.

What Makes Fiber Lasers Faster and More Efficient?

Fiber lasers work faster than other types of lasers due to their high energy density and smaller focus spot. This results in quicker cuts and less material wastage. They also require less maintenance and have a longer lifespan, making them a cost-effective choice for steel laser cutting services.

Common Uses of Fiber Laser Cutting in Manufacturing

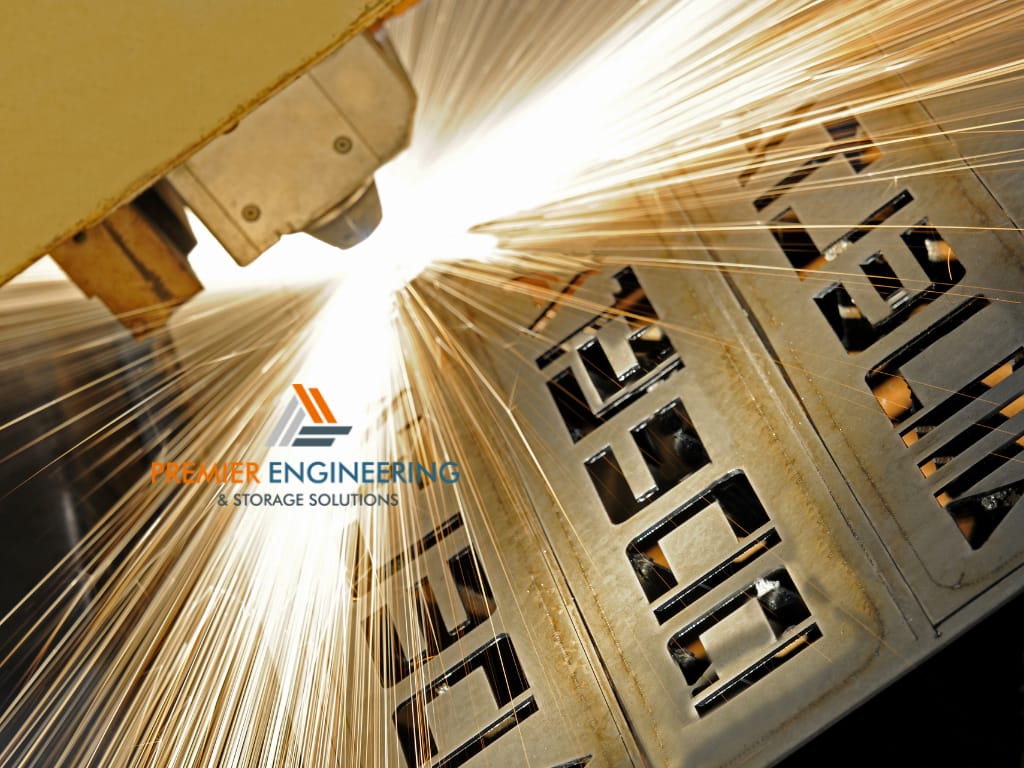

Fiber laser cutting is widely used in industries like automotive, aerospace, and construction. It’s perfect for cutting steel sheets, creating metal components, and crafting detailed designs. Its ability to handle tough materials while maintaining precision makes it a favorite for manufacturing and CNC cutting services.

Nd:YAG and Nd:YVO4 Laser Cutting: Specialized Precision

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) and Nd:YVO4 (Neodymium-doped Yttrium Orthovanadate) lasers are specialized types of lasers used for highly precise applications. They are less common than CO2 or fiber lasers but are essential for specific industries.

What Are These Types of Lasers, and How Do They Work?

Nd:YAG and Nd:YVO4 lasers use solid crystals to generate a powerful laser beam. These lasers are ideal for applications requiring fine details, such as engraving or drilling small holes. Their precision makes them useful for tasks like intricate steel metal cutting.

When to Use Nd:YAG or Nd:YVO4 for Steel Metal Cutting

These lasers are often used for specialized steel laser cutting services, particularly when extreme precision is needed. They are not as fast as fiber lasers but excel in areas where detail and accuracy are more critical than speed.

Applications in Jewelry, Electronics, and More

Nd:YAG and Nd:YVO4 lasers are frequently used in jewelry making, electronic component manufacturing, and medical device production. Their ability to produce clean, detailed cuts makes them invaluable for these industries.

CNC Cutting Services vs. Laser Cutting: What’s the Difference?

CNC cutting services and laser cutting are two popular methods for shaping materials. While they share some similarities, they are suited for different needs.

How Do CNC Cutting Services Work?

CNC (Computer Numerical Control) cutting services use machines that are programmed to cut, shape, or mill materials. These machines rely on mechanical tools like drills, lathes, or saws to perform precise cuts. CNC cutting services are versatile and work well with a wide range of materials, including metals, plastics, and wood.

The process is perfect for tasks like milling complex 3D shapes or creating detailed engravings. However, CNC cutting may require more finishing work compared to laser cutting.

Advantages of Laser Cutting Over Traditional CNC Cutting

Laser cutting has several advantages over CNC cutting, especially for intricate designs and detailed work. The laser beam allows for higher precision and smoother edges, eliminating the need for additional finishing. It’s also faster for tasks like steel metal cutting and offers greater flexibility with material thickness and design complexity.

Laser cutting is ideal for industries needing high-quality results, such as steel laser cutting services. It’s especially useful when clean, precise cuts are a priority.

When to Choose CNC Cutting Services Instead of Laser Cutting

While laser cutting excels in precision and speed, CNC cutting services are better for certain tasks. If you’re working with thicker materials, need 3D shaping, or are cutting materials not compatible with lasers, CNC cutting is the way to go. It’s also a cost-effective option for simpler, large-scale projects that don’t require intricate details.

Choosing the Right Type of Laser Cutting for Your Project

Selecting the right laser cutting method depends on several factors, such as the material, design complexity, and end use of your project.

What Factors Influence the Choice of Laser Cutting Method?

When deciding on a laser cutting method, consider the material type, its thickness, and the level of precision needed. For example, fiber laser cutting is best for steel metal cutting, while CO2 lasers excel with non-metals like acrylic and wood. The speed and cost of the process also play a role in choosing the right method.

How Material Type, Thickness, and Design Play a Role

Thicker and tougher materials like steel require powerful lasers, such as fiber lasers, to ensure clean and accurate cuts. On the other hand, thinner materials or intricate designs may be better suited for CO2 laser cutting. Understanding your project’s needs will help you choose the most efficient and cost-effective solution.

Why Steel Laser Cutting Services Are a Popular Option

Steel laser cutting services are highly sought after because of their ability to handle tough materials with precision. From automotive parts to construction components, laser cutting ensures accurate and durable results. It’s also faster and more reliable than traditional cutting methods, making it a preferred choice for many industries.

Conclusion: Why Laser Cutting Is the Future of Precision Manufacturing

Laser cutting has transformed the way materials are shaped and designed. Its precision, speed, and versatility make it a valuable tool in modern manufacturing.

How Laser Cutting Revolutionizes Steel Metal Cutting

Laser cutting has made steel metal cutting more efficient and precise. It allows manufacturers to produce clean edges and complex designs without wasting materials. This level of precision was hard to achieve with older methods, making laser cutting a game-changer for industries that rely on steel components.

Why More Businesses Are Turning to Steel Laser Cutting Services

Businesses are increasingly choosing steel laser cutting services for their speed and accuracy. The ability to handle a wide range of materials and create custom designs gives companies a competitive edge. Additionally, laser cutting reduces production times and minimizes errors, leading to cost savings in the long run.

The Growing Demand for CNC Cutting Services and Beyond

While laser cutting is a preferred method for many, CNC cutting services continue to play an important role. For tasks requiring 3D shaping or specific material handling, CNC cutting remains a reliable option. Together, these technologies are paving the way for more efficient and precise manufacturing solutions.